Portable USB Connect Tech Specs

Interested in the tech specs for the Portable USB Connect? Keep reading to learn more!

- Protocols Supported: Xon/Xoff, software handshaking, RTS/CTS hardware handshaking & X-modem

- Supports drip-feed for the above Protocols (if CNC has function active)

- Baud Rates: 1200 – 115,200 supported

- Configurable Data/Parity/Stop Bits

- Includes 4 Line Display & AC Power Supply

- Optional FANUC Power cable can be used for FANUC controls

- Also supports Fadal X-modem/Fadal file transfers and Haas X-modem

- Includes Thumb Drive (can use any brand/size)

- Mid-tape restart

- Connects to RS232 serial port on CNC & no special software required

- Configurable Line Delay & EOB CR/LF

- 1 Year Warranty with free phone Support for device

- Quick Setup Guide & Complete Operation Manual

- Compared to the Pendant USB, it saves four hours of time not needed for installation & does not need to be dedicated to one machine

Other USB Connect Models to Consider

If Portable USB Connect doesn’t seem like the right hardware for your facility, there are other models to consider as well, including:

USB Connect Pendant Model

- Easy to install pendant mount

- Includes 4 line LCD display & 1GB Thumb Drive

- Mid-tape start with search function, end of block character control, & more

- Connects via RS232 serial port with USB directory listing

- Eliminates the need for expensive memory upgrades

- Software, Hardware & Xmodem flow control for any CNC

USB Connect Switchbox Model

- Built-in Switchbox function controls data flow into CNC machine from PC

- Allows machine serial port to feed between external cable connection & USB Pendant device

- Pendant USB Connect & secondary system connects to the serial port on CNC Machine

- Operator can load from USB Drive to CNC when external Serial port device is down

USB Connect Mazak Model

- Pendant mount USB Connect – Mazak model controller

- For Mazatrol (CMT) programs

- Comes with 1GB USB Flash Drive

Contact Shop Floor Automations for help with Portable USB Connect!

If you want to utilize Portable USB Connect or any of the other USB Connect models, contact Shop Floor Automations today. We have over years of experience when it comes to automating shop floor equipment and we’ll be happy to help you do the same. Take advantage of the ability to drip-feed to CNC machines and load and save programs with Portable USB Connect by calling us today at (619) 461-4000!

To learn more about the USB Connect hardware and shop equipment automation services that we offer to make your shop floor more efficient, visit us on the web at Shop Floor Automations.

Are you contemplating whether you should implement machine monitoring on your shop floor? With machine monitoring from Scytec DataXchange and the help of Shop Floor Automations, you can really take your operations to the next level.

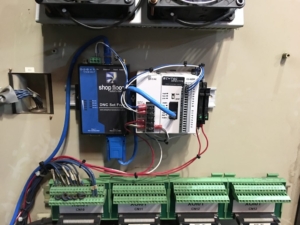

Are you contemplating whether you should implement machine monitoring on your shop floor? With machine monitoring from Scytec DataXchange and the help of Shop Floor Automations, you can really take your operations to the next level. If you are utilizing Scytec DataXchange, you may need to implement hardware with your shop floor equipment. That is where the Status Relay Controller comes into play. This device comes in two versions, SRC Standard and SRC Extended. Shop Floor Automations can help you determine which is right for your shop floor equipment.

If you are utilizing Scytec DataXchange, you may need to implement hardware with your shop floor equipment. That is where the Status Relay Controller comes into play. This device comes in two versions, SRC Standard and SRC Extended. Shop Floor Automations can help you determine which is right for your shop floor equipment. Allowing your CNC machines to communicate effectively is essential for maintaining strong shop floor operations. However, strict network security can make that task harder with firewalls and other security measures. Thankfully, by implementing Predator Secure DNC at your facility, you can eliminate the requirements of your corporate domain.

Allowing your CNC machines to communicate effectively is essential for maintaining strong shop floor operations. However, strict network security can make that task harder with firewalls and other security measures. Thankfully, by implementing Predator Secure DNC at your facility, you can eliminate the requirements of your corporate domain. USB Connect solutions can eliminate the old technology on your CNC machines. They can also increase storage at the machine and allow you to store large part programs and use drip-feeding and other controls. By eliminating older technology like floppy disks, you can increase the efficiency of your shop floor and improve overall productivity.

USB Connect solutions can eliminate the old technology on your CNC machines. They can also increase storage at the machine and allow you to store large part programs and use drip-feeding and other controls. By eliminating older technology like floppy disks, you can increase the efficiency of your shop floor and improve overall productivity.