SFA Press Coverage

20 years in business. 20 years of success stories. 20 years of insight.

Our customers want information on solutions before they invest. This is why Shop Floor Automations proudly shares our appearances in many manufacturing trade publications throughout the years.

We wish to highlight not only product features but results via manufacturing automation case studies. Check out our most popular stories below, and keep scrolling for more articles!

Most Popular Stories

Q&A with Shop Floor Automations: What does the future hold for manufacturers and automation technology?

We see manufacturing shifting from a people-strained to a people-enabled industry, where skilled workers are receiving intelligent assistance from automation technology to allow them to have the freedom to focus on activities that have the greatest effect on the company. Read more at manufacturingtomorrow.com.

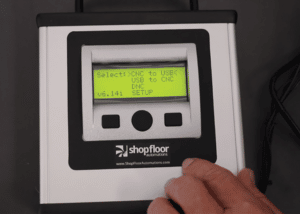

Why You Should Skip Free DNC Software

Automation & Networking, Additive & 3D Printing | Shop Floor Automations | cad, CNC, Computational Design

The benefits of DNC software when it comes to managing your CNC programs, machine parameters, and offsets are well known. As a result, many businesses look to offer some form of DNC software or their own, ranging from thousands of dollars to absolutely free. While free DNC software options may seem like a great deal, the limitations they create are often detrimental to your business.

To read the rest of the article click here.

Cloud OEE Monitoring

Manufacturing News, April 2019 – Benefits to DataXchange Cloud CNC Monitoring

Cloud machine monitoring from DataXchange was discussed in Manufacturing News on page 94 of the West edition.

Low cost, the same features as on-premise software and the lack of commitment needed are the top three benefits discussed.

We also appeared in the Southeast edition on page 47 for this month.

Legacy Equipment

CNC West, April/May 2019 – Hardware updates for older MFG equipment

Page 52 of CNC West for the April/May 2019 issue features a full page article on our CNC shop floor hardware.

Our hardware acts as a DNC software alternative for smaller shops, as well as acting as a means to replace old media. This old media includes floppy disks, old RS232 cabling and updating RS232 ports.

We also had one of our ads appear on page 66 about our solutions.

Rise Up Industries

Modern Machine Shop, March 2019 – Predator MDC Updates & News on a Good Cause

Modern Machine Shop has featured Rise Up Industries in their recent issue. The educational program is local to us here in San Diego County and we are so excited they made the pages of this publication.

Shop Floor Automations worked closely on this collaboration – you can see the original length article on the MMS blog. The print piece appears on pages 82 to 85.

The same piece featuring updates to Predator MDC that appeared in another publication this month made an appearance in MMS. This can be found on page 136.

Machine Data Collection Updates

Manufacturing News, March 2019 – Updates to Predator MDC Software

Updates and benefits of Predator MDC have been shared by Manufacturing News on page 90 of the Midwest issue.

Items discussed in the article include:

- Tracking options, including wireless, Ethernet, RS232

- How MDC helps with lean production, continuous improvement, and quality

- Included drip-feeding and integration possibilities

- Compatibility with MTConnect and other protocols

Results from an MDC case study discussed

CNC Monitoring Interface

Manufacturing News, February 2019 – DataXchange’s new Operator Data Interface

Manufacturing News has shared a machine monitoring product update from Shop Floor Automations on the front page of their February issue! The article focuses on the Operator Data Interface (ODI) from DataXchange.

The ODI replaces the previous Data Entry feature for the software. This was a cover story for the West edition and continues on page 68.

You can also check out our advertisement about DataXchange from SFA on page 12.

2019 Buyers Guide

Production Machining Magazine, January 2019 – SFA is on the publication’s Software buying lists

Shop Floor Automations is thrilled to once again be included in the Production Machining Magazine January 2019 Buyers Guide. This list is a must for manufacturers.

Here’s where our company appears:

- Software > CAD/CAM and Related Software (page 78)

- Software > ERP & Other Shop Management Software (page 79)

- The main directory (page 112)

CNC MDC Case Study

MFG News, December 2018 – Arizona manufacturers use Predator MDC to collect machine data and improve OEE

R&D Manco in Arizona was featured in MFG News via a case study using Predator MDC from Shop Floor Automations.

While the company invested in CNC Editor and hardware a few years prior, they discuss the results of also implementing an on-premise machine data collection system.

Read more about how MDC helped with month-over-month gains, increased machine capacity and improved shop floor communication.

Hardware MFG Case Study

Today’s Medical Developments, November/December 2018 – Ohio manufacturers increase productivity with hardware upgrades

Fredon Corporation in Ohio was featured in a case study from Today’s Medical Developments.

The manufacturers use Shop Floor Automations hardware to bridge a technological skills gap.

Read how their investments of the Portable USB Connect, the Pendant USB Connect, and the Floppy Connect helped their operations.

Automation Return On Investment

MFG News, November 2018 – Ways to show decision makers the value of automation

On page 61 of the West edition of MFG News, methods to display the value of manufacturing automation are laid out in this article.

Different methods are discussed on:

- How to find and lay out ROI possibilities

- Use examples with your shop’s equipment

- Give alternative options

- Concerns with price were also explored

Three OEE Monitoring Benefits

MFG News, October 2018 – Machine Monitoring benefits are reviewed in this issue

On page 56 of the Midwest edition of MFG News, the article declares:

Benefit 1 – This system can integrate with other software to help optimize machine capacity.

Benefit 2 – Machine monitoring is not just for CNC machines.

Benefit 3 – Machine monitoring helps operators working at machines convey important information to those not working on the shop floor.

Hardware bridges manufacturing technology gap

Today’s Medical Developments, October 2018 – Fredon Corp., needing a quick and easy solution to help load/unload CNC programs, found results with Shop Floor Automations’ Portable USB Connect.

USB hardware helps to bridge a technological skills gap at Fredon Corporation.

Machine Monitoring In Focus

Manufacturing Engineering, September 2018 – OEE Monitoring Advertisement

Shop Floor Automations has been a Scytec DataXchange reseller for many years. The software helps manufacturers with real-time machine monitoring.

Page 22 of Manufacturing Engineering features an ad on SFA’s services with DataXchange. Be sure to also ask us about starting up a trial and how you can go up against manufacturing downtime for as little as $50 per month!

Machine Monitoring Classes

MFG News Magazine, July 2018 – The DataXchange E-Learning program is discussed

MFG News dedicated an entire page in their Southwest issue about DataXchange’s E-Learning system! “In order to obtain the goals of lean manufacturing, overall equipment efficiency and increased machine capacity, the user needs to know the best ways to utilize DataXchange to make better shop floor decisions. With E-Learning, the user should be able to achieve the benefits of increased utilization and decreased downtime with proper use of the software.”

Manufacturing Engineering

Manufacturing Engineering Magazine, July 2018 – An advertisement and interview are featured

In this issue, we placed an advertisement on page 22 of Manufacturing Engineering that highlights some basic manufacturing productivity monitoring benefits.

We were also pleased the publication featured an interview with our resident hardware expert Guy Barrow, where he focuses on shop floor upgrades, pages 62 through 63.

DataXchange E-Learning

CNC West, June/July 2018 – Machine monitoring learning system is featured

Page 54 highlights a piece from Shop Floor Automations detailing the DataXchange E-Learning program. “E-Learning is a series of online courses that DataXchange users can take at their own pace, at any time. Topics covered include: configuring reporting options, shift options, software installation, initial configuration, modifying existing machine data, system administration, and understanding the machine data collection sources”

New CNC Hardware

Modern Machine Shop, June 2018 – A full page feature on new SFA hardware

Thanks to Modern Machine Shop for having us in their 90th-anniversary issue the same year as our 20th anniversary! We were graciously given a full-page spread on our LAN-USB Hardware device, which adds Ethernet and USB to CNC machines.

Add Ethernet, USB to CNCs

MFG News, June 2018 – Our hardware plus aerospace OEE monitoring are featured

Our new hardware device, the LAN-USB Connect, combines adding Ethernet to machines, as well as CNC to USB functionality. The publication MFG News also highlighted our evaluation of why machine monitoring for aerospace manufacturers is crucial on the front page!

Monitor Aerospace Production

CNC West, April/May 2018 – Machine monitoring for the aerospace manufacturing industry

Aerospace parts manufacturers are given the best reasons why monitoring their utilization will help with productivity. SFA also appears in an advertisement in this issue for our overall line of manufacturing productivity solutions.

SFA: Two Decades in Business

Modern Metals, April 2018 – SFA’s 20th anniversary as a manufacturing systems integrator

Shop Floor Automations is proud to have serviced the manufacturing industry for two decades and counting. Thank you to Modern Metals Magazine for publishing a press release about our 20th anniversary!

Medical Manufacturing

MFG News, April 2018 – Machine monitoring for the medical manufacturing industry is highlighted

Making medical parts is a high volume industry. Machine monitoring overall equipment efficiency (OEE) is broken down into four parts: utilization rate evaluation, tracking more than downtime, what machines are eligible for the software, and how to use machine monitoring as a step towards lights-out manufacturing.

Metal Forming Solutions

MetalForming Magazine, March 2018 – 20th anniversary of SFA features new logo and refreshed website

“Shop Floor Automations, La Mesa CA, a manufacturing integrator, announced its new website and logo as part of its 20th anniversary. The company specializes in assisting manufacturers to increase productivity. Solutions offered include DNC software, machine monitoring…improving legacy machines, and replacing old media.”

SFA in Manufacturing News

MFG News, March 2018 – 20th anniversary of Shop Floor Automations is discussed

“SFA technicians are well versed in dealing with CNC machines, as well as Industry 4.0 and protocols such as MTConnect. Customers of SFA also find themselves surprised when technicians can diagnose and fix other problems they were not even aware of previously. Technicians can also service customers over the phone and via remote services.”

Machine KPIs, CNC Metrics

Modern Machine Shop, February 2018 – Machine monitoring software benefits explored

“DataXchange machine monitoring system reduces downtime by providing live notifications of machine issues via text or email…dashboards enable manufacturers to communicate with employees about productivity…key performance indicators (KPIs) and overall equipment effectiveness data.”

Manufacturing Buyer’s Guide

Production Machining Magazine, January 2018 – Annual recommendations of what to invest in for the shop floor

Find Shop Floor Automations in the 2018 buyer’s guide under Software>CAD/CAM, Software>ERP & Other Shop Management. We are also located under Software>Data Collection Devices, as well as the general directory. The annual guide helps shop floor decision makers choose from a variety of productivity solutions.

Monitor Machine Hog Outs

Modern Machine Shop, January 2018 – Machine data collection from SFA is featured

“Machine monitoring has been another important factor in R&D Manco’s success,” states MMS editor Peter Zelinski. “Gathering basic data on machine status, and studying the data to diagnose and remedy the causes of non-cutting time, has been the shop’s most powerful resource for realizing machining capacity improvements.”

Top Utilization Monitoring Benefits

MFG News, October 2017 – SFA discusses top benefits of machine data collection

Among many machine monitoring benefits, the unexpected equipment that can be monitored is one. “We can work with manual machines, autoclaves, paint lines, PLC-driven machines and more,” said a company spokesperson. “Unconventional machine monitoring is something we are known for and can be an ideal solution for some companies.”

Job Shop Cuts Cables to Save Time on Data Transfers

Modern Machine Shop, Oct 2017. At Stollen Machine & Tool Co., uninsulated cables could not reliably transport CNC programs from the computer to the machines. Six wireless RS232 units from Shop Floor Automations have resulted in 15 percent daily time savings.

This customer was able to gain 15 percent more time each day with wireless hardware.

Wireless CNC Hardware Case Study

Modern Machine Shop, October 2017 – Hardware helps manufacturer gain time daily

How did one manufacturer gain back 15% more time each day? “To keep his shop thriving, Mr. Stollen is committed to updating old, outdated and unreliable technology such as the flawed cable system for transferring data. Often, when he transferred CNC programs…only parts of the code would make it to the machine. Other times, none of the code would make it to the machines.”

Reasons for Machine Monitoring

Manufacturing News, August 2017 – Machine monitoring software ad

Reasons to invest in machine monitoring is discussed in an advertisement. SFA is here as a resource for manufacturers for solutions such as CNC networking, OEE monitoring, floppy drive emulators, wireless CNC transfers, and more.

Article on Wireless CNC Transfers

Manufacturing News, June 2017 – the WiFi USB product is explored

The WiFi USB product from Shop Floor Automations is highlighted in this issue of MFG News. If you wish you could transmit data from an old machine in your shop wirelessly but thought it was going to cost a great amount of money, get ready to be surprised.

Tip of the Month – Monitoring Moldmaking

Moldmaking Technology Magazine, May 2017 – monitoring the moldmaking process

“For mold manufacturing, these processes may take some time, maybe hours, to produce a single part. Mold shops need to know how long it is going to take to get that mold out the door and what may be preventing that from happening.”

CNC Floppy Drive Replacement

CNC West, April/May 2017 – Go wireless or replace floppy disks for machines

“The WiFi USB Connect allows machinists to access files via a shared network folder, eliminating the need to seek out a programmer for assistance…If being stuck with old media is a concern, machines that use floppy disks can be updated with modern devices.” – See our article on Page 73 and our advertisement on page 69

Going Wireless for Older CNC Machines

Modern Machine Shop, May 2017 – The WiFi USB Connect device is profiled

“Shop Floor Automations offers a device that adds Wi-Fi to any machine via a USB port for data monitoring. Intended to serve as a cost-effective solution for older machines, the Wi-Fi USB Connect emulates a thumb drive and plugs into the USB port of a machine and enables it to connect wirelessly to a shared folder on the network.”

Machine Monitoring – Anywhere, Anytime

Modern Machine Shop, March 2017 – Ad informing customers about machine monitoring

On page 109 in Modern Machine Shop for this issue, we ran an advertisement wishing to inform customers about the flexibility of machine monitoring software. The ad displays different ways that the software can be accessed, as well as being supported by the MTConnect protocol and machines of any make/age/model.

Easy Machine File Transfers

MoldMaking Technology, January 2017 – Big button interface for machine operators

“In addition to USB capabilities, Ethernet protocols include FANUC FOCAS, Windows Share and FTP. FOCAS allows file transfers to and from CNC memory…It also can be leveraged for machine monitoring in the future without the added cost of hardware.”

CNC Machine HMI Interface

Modern Machine Shop, January 2017 – Touch HMI provides overall ease of use

Predator Touch HMI through Shop Floor Automations was a hit product this month, with its capabilities to make all actions across the shop floor easier and more efficient. “While Touch HMI is the front end for machinists, multiple Ethernet protocols can be used on the back end.”

New Features for OEE Monitoring Software

CNC West, December 2016/January 2017 – New machine monitoring features available

“New features include an MTConnect Data Viewer…The Real-Time Viewer has been updated, adding the ability to copy RTV screens to groups or users, as well as new reports and charts like Operation Time, plus the OEE Equipment Summary. ” – Page 66

PC to CNC Transfers

MoldMaking Technology, December 2016 – USB device for wireless transfers

“Shop Floor Automations (SFA) has re-branded its hardware line of products as the Connect Series and is in the testing stages for its latest release, the WiFi USB Connect, a wireless USB solution for the shop floor. The device emulates a USB stick, allowing the user to share data between a PC and a machine with a USB port.”

Machinist Comic Strip

MFG News, December 2016 – Manufacturing comic strip character Shop Floor Man debuts

“You have middle school kids, high school teens and college-aged young adults who we are trying to get into this industry, or people like the military veterans being trained…These people of these various age groups are attached to their devices and social media – we can reach them and show them this industry is a community.”

CNC Wireless USB

The Fabricator, November 2016 – Hardware accomplishes PC to CNC machine abilities

“Gives wireless abilities to floppy drive emulators and CNC machines with a USB port…Data sources include network shares, FTP, email, SMB, and Cloud services. Users will see the files at their machines on the USB as soon as they are added to the shared folder. They will not need to walk to the programmer or find them to get needed answers.”

SFA in MFG News

MFG News, October 2016 – Touch HMI is once again featured in this publication

“Using Touch HMI’s big button interface, operators can enjoy features that simplify sending and receiving programs to and from machines. For shops employing machine data collection, they can put in downtime codes that the operators can choose, such as set up or preventative maintenance, for example.”

Moldmaking OEE Monitoring

MoldMaking Technology, March 2016 – Monitoring the moldmaking process

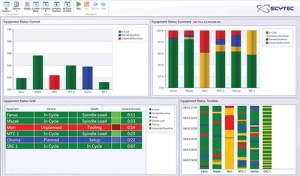

“Scytec DataXchange software from Shop Floor Automations (SFA) is a machine monitoring software that provides detailed data collection and real-time reporting on a dashboard, enabling users to instantly track productivity, and plan for increased efficiency and time savings on the shop floor.”

CNC Machine Monitoring Cover Story

Modern Machine Shop, February 2016 – Machine monitoring helps with productivity and downtime

“Implementing machine monitoring software…was an almost immediate 5-percentage-point improvement in measured performance. That boost was the early return on [investment] simply paying attention to this performance for the first time.”

Hardware for Lights Out Manufacturing

MOXA Case Study, 2016 – SFA Hardware networks CNCs to machine monitoring system

“With a combination of hardware and software, a CNC monitoring system would collect, analyze, and visualize the necessary performance metrics.”

Cloud-Based Monitoring Improves Aerospace Manufacturer’s Productivity

Modern Machine Shop Online, 2014 – Cloud-based machine monitoring from Shop Floor Automations enabled aerospace parts manufacturer Tech Manufacturing to reduce lead times and improve productivity.

Cloud-based machine monitoring from SFA enables aerospace manufacturer Tech Manufacturing to reduce lead times and improve productivity.