-

- Ease of Use

When selecting machine monitoring software, you need to select an option that is easy to use for everyone. That includes everything from operators and executives to managers. Examine the user interfaces and ensure that whatever software you choose is easy to use for all parties.

-

- On-Premise vs. Cloud-Based Monitoring

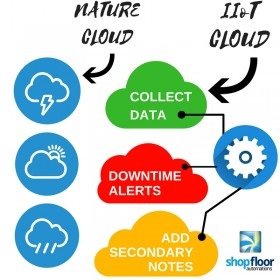

There are two types of monitoring solutions, cloud-based and on-premise. On-premise is where the data is stored on-site with your server and database. While this is often a cheaper option, there are limitations. Cloud-based monitoring allows anyone with access permissions to view the data from anywhere since it is stored in the cloud. With any internet-enabled device, you can view the data. Cloud-based monitoring also reduces the IT support required, because you do not need to buy or maintain expensive on-site servers. Whatever your preference, Scytec DataXchange offers both types of machine monitoring.

-

- Service – Training and Support

Something else to keep in mind is the customer service and support that you will receive. A lot of machine monitoring platforms provide initial training and customer service for initial issues, but that’s where the support stops. With Scytec DataXchange and Shop Floor Automations, you will get continual support and service to ensure that everything works properly. Our cloud model include support in the cost, so we must win your business each month.

-

- Analytics

When it comes to choosing the right machine monitoring software, you should also consider what analytics are offered. The data collected is pretty similar across platforms, but how that data is used and what reports can be produced vary widely. Be sure that the machine monitoring software you choose has the right data and analytics for your process. Your definition of a machine cycling may be different for different equipment since all machnes are not the same. Tool changes, multiple spindles, warm-up programs, and maintenance procedures also should be consider when looking at the data and how it’s acquired by the software.

What Machine Monitoring Solution Does Shop Floor Automations Recommend?

At Shop Floor Automations, we want our clients to have the best. That is why we recommend Scytec DataXchange for machine monitoring. This software is available in an on-premise or cloud-based package and starts at only $45 per month.

Overall, Scytec DataXchange offers the following specs:

- On-Premise or Cloud-Based

- Starts at $45 per machine, per month, via Cloud

- We house the servers – you provide the data!

- Real-time data from any CNC control/equipment, regardless of the machine age

- Unlimited number of reporting and charting licenses

- View & report on your data results from anywhere

- Track multiple types of cycle time

If you want to take advantage of everything Scytec DataXchange has to offer as a machine monitoring software, Shop Floor Automations can help! Since , we’ve been offering assistance implementing machine monitoring software and we would be happy to do that same for you. Give us a call today at (619) 461-4000 to learn more or request a quote.

To learn more about the machine monitoring solutions and other hardware and software solutions that we offer, visit us on the web at Shop Floor Automations.

Industrial IoT is the future of manufacturing because it allows plans to reduce costs and improve productivity and profitability without compromising product quality. However, if you want to truly take advantage of what IIoT can offer, you need to have accurate and real-time data to work with. That is why machine monitoring software is so essential to have.

Industrial IoT is the future of manufacturing because it allows plans to reduce costs and improve productivity and profitability without compromising product quality. However, if you want to truly take advantage of what IIoT can offer, you need to have accurate and real-time data to work with. That is why machine monitoring software is so essential to have.

OEE stands for overall equipment efficiency and is tracked via the data obtained through machine monitoring software. By incorporating the Industrial Internet of Things (IIoT) and machine monitoring solutions, you can improve your overall OEE.

OEE stands for overall equipment efficiency and is tracked via the data obtained through machine monitoring software. By incorporating the Industrial Internet of Things (IIoT) and machine monitoring solutions, you can improve your overall OEE.

Do you need to connect your Fadal machines? With USB to Fadal, you can not only achieve Fadal file transfers but also increase program storage and streamline loading. That means upgrading your shop without buying expensive new equipment. Regardless of your number of machines, types of machines, or the types of controls, Shop Floor Automations has you covered.

Do you need to connect your Fadal machines? With USB to Fadal, you can not only achieve Fadal file transfers but also increase program storage and streamline loading. That means upgrading your shop without buying expensive new equipment. Regardless of your number of machines, types of machines, or the types of controls, Shop Floor Automations has you covered.