Manufacturing productivity does not happen or improve from luck. It comes from preparation, research and implementation.

What kind of manufacturing plan should you make for 2019, and for the foreseeable future? Whether you are an independent shop or a large production operation, you need to think about the bigger picture.

This is definitely a topic that manufacturers are thinking about lately. A whitepaper from SME ToolingU states:

- 80% say that machine availability (OEE) is a priority

- 60% of manufacturers say continuous improvement is a priority

- 56% state that production planning is priority

We felt particularly inspired by a Modern Machine Shop article in their December 2018 issue. Mark Albert wrote about IIoT road maps, and while solutions vary for shops, the basic steps of the plan work for anyone.

“The roadmap shows where a manufacturing company is starting out,” Mark states. “Then defines how to proceed along a continuous series of implementations.”

Here are the manufacturing productivity steps you should be taking:

- 1) DISCOVER – Look at your current productivity state, trends in technology and the initial idea of what you want to implement.

- 2) DEFINE – Think of the problem at hand deeply. Will the solutions you were initially thinking of investing in fix these issues? Will it integrate with any existing tools you have on hand, such as CAD-CAM or ERP?

- 3) ANALYZE – Evaluate the digital maturity of the solution. Who will this come naturally to, who will adapt to it and who will reject it?

- 4) VALUE – Look at the scope of the project, map out ROI, see if you can take place in a pilot or trial, and read case studies. Have proof of why it is beneficial!

- 5) EVOLVE – Once you have invested in and adapted to the solution, go further. For example, in machine monitoring – expand to different machines, learn more features past basic functions, or upgrade to different versions to gain more benefits.

- 6) IMPROVE – Aim for continuous improvement in manufacturing. Even if you get your OEE to a specified goal in a certain amount of time, why not aim higher?

Ready to get started? Call (877) 611-5825 or have us contact you

We often encounter customers who are running old versions of Microsoft on their shop floors. We strongly advise that customers read this quick blog on Windows 10 migration for your manufacturing operation.

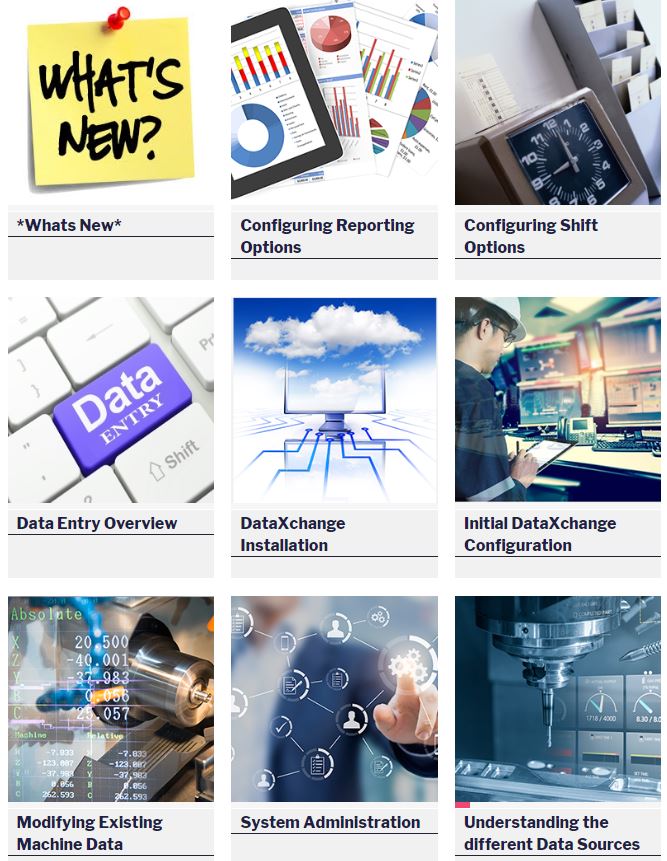

We often encounter customers who are running old versions of Microsoft on their shop floors. We strongly advise that customers read this quick blog on Windows 10 migration for your manufacturing operation. Picking up a new software system can be challenging. DataXchange makes the process easy with lots of resources.

Picking up a new software system can be challenging. DataXchange makes the process easy with lots of resources. Haas Automation is celebrating the 30th anniversary of their Haas VF-1 vertical machining center with Haas Demo Day 2018!

Haas Automation is celebrating the 30th anniversary of their Haas VF-1 vertical machining center with Haas Demo Day 2018! We get many calls to our office asking questions about CNC floppy emulator hardware. While we invite you to contact us for more detailed information, we want to answer the most asked question: Does your Floppy Connect hardware add memory to my machine?

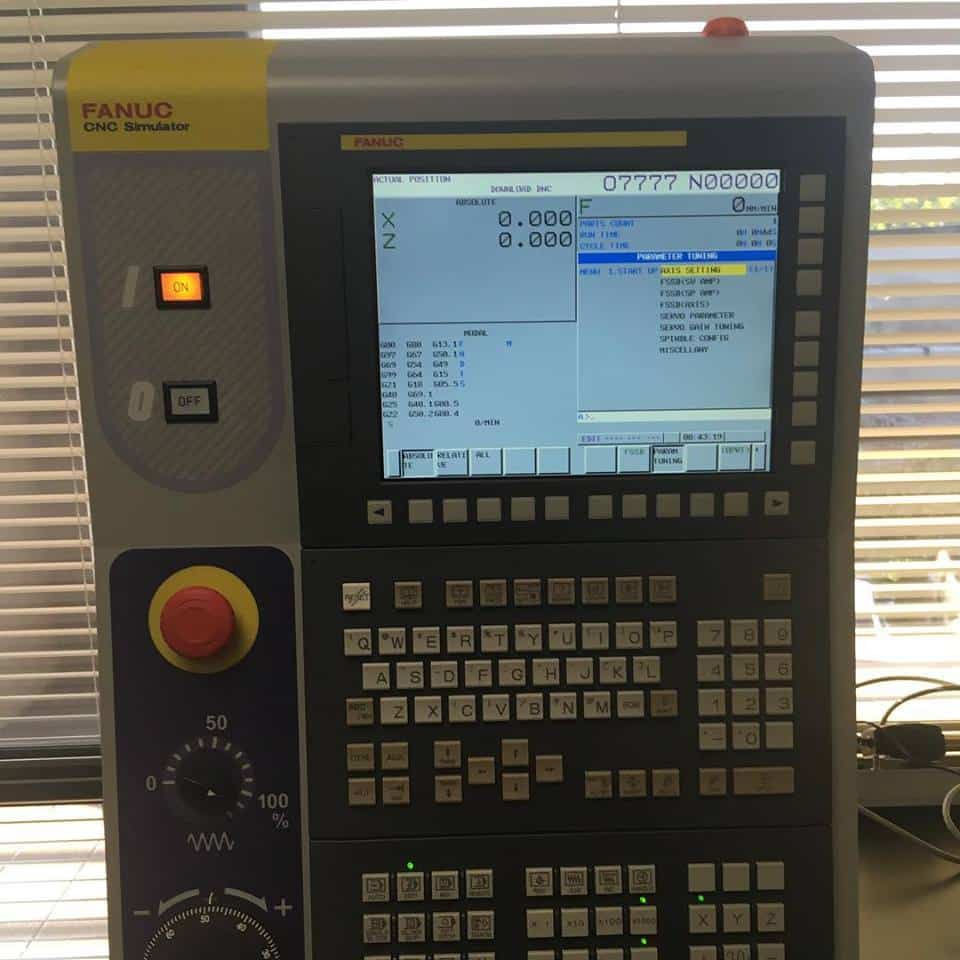

We get many calls to our office asking questions about CNC floppy emulator hardware. While we invite you to contact us for more detailed information, we want to answer the most asked question: Does your Floppy Connect hardware add memory to my machine? How many programs you can store on the USB stick is another big question we get. Since the customer is going from a disk that was once 720k or 1.4MB to a 1GB SFA USB stick, the assumption is that they can store and send big programs from it. This is incorrect.

How many programs you can store on the USB stick is another big question we get. Since the customer is going from a disk that was once 720k or 1.4MB to a 1GB SFA USB stick, the assumption is that they can store and send big programs from it. This is incorrect.

The manufacturing industry is experiencing a lot of growth. This also creates a demand for machinist stress relief resources.

The manufacturing industry is experiencing a lot of growth. This also creates a demand for machinist stress relief resources.