“Everything we have today is the result of going to Chicago, walking through those doors of IMTS, and seeing all the amazing technology. It’s a great atmosphere. It’s like walking into a living room that’s set up as a CNC shop with people smiling and ready to help you.”

— Ashley Miller, Co-owner, ARC EDM

For those who attended the International Manufacturing Technology Show (IMTS) 2022, like Miller, they know that there was plenty to keep over 86,000 registrants from 110 countries interested in the 1,816 exhibitors. IMTS 2024 promises much more, with many new product launches and networking connections anticipated over the course of the six-day event.

New Products, New Connections

ZOLLER (booth #432018), for one, plans to introduce its >>coraMeasure LG<< automated tool measurement system to improve tool measurement precision and speed by delivering tools to a linear robot that removes tools from the pallet and moves them to a ZOLLER >>venturion<< presetting and measuring machine. Each tool is identified with the ZOLLER >>dChip<< system and tool data is stored in the ZOLLER z.One database and accessible anywhere.

The new HAIMER (Booth #431510) Automation Cube One will also make its debut at IMTS 2024. This fully automatic robotic cell can shrink fit a tool, measure it and send the data to the machine tool in just 60 seconds. The Automation Cube One features a FANUC cobot for handling of tool assemblies and a Siemens Sinumerik One CNC control.

DataXchange, available through IMTS machinoe monitoring exhibitor Shop Floor Automations, has released new protocol for supported equipment brands, including Okuma, Heidenhain and Siemens.

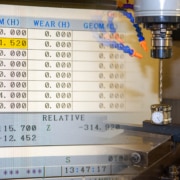

For those exploring machine monitoring and data collection solutions, Scytec Consulting (Booth #133240) has released new protocol for machine brands like Okuma, Heidenhain and Siemens to connect more data points for greater depth and analysis of equipment on the shop floor with its DataXchange equipment monitoring software. The added collection of Siemens spindle speed rates, for example, can help identify faults for better finish and surface quality due to consistent cutting speed at the tool cutting edge.

The partnership between Scytec and CGTech’s VERICUT® takes machine monitoring a step further through digital twins to simulate your manufacturing environment and identify the presence of variances before production begins on the floor, thereby minimizing or eliminating non-conformances and rework. Attendees seeking an IMTS machine monitoring exhibitor will have first access to the latest Post Check feature of CNC Machine Connect, in which users may replay stored, live-streamed data from the program for even greater visibility and predictive accuracy of your simulations.

Greg Mercurio, president of manufacturing integrator Shop Floor Automations, says that “It’s the relationships that we start and build at IMTS that make the show such a vital experience. Not only are we able to demonstrate the latest advances in our technology portfolio, but our deep customer connections allow us to match the right solution and service to their environment so they can focus on their producing high-quality product.”

To plan your IMTS show with these exhibitors and others, visit www.imts.com.

Mercurio likens machine monitoring to a wearable fitness tracking device. “Even if you achieved your ideal weight, if you’re not monitoring your heart rate, fitness levels and sleep quality, you’re going to have a harder time detecting the signs of a heart condition or other potential health problem,” he says. “The same thing applies to machine monitoring. If you maximized your Overall Equipment Effectiveness (OEE) and stopped monitoring your equipment, it’ll be that much more difficult to proactively identify abnormalities or anomalies before they become major concerns.”

Mercurio likens machine monitoring to a wearable fitness tracking device. “Even if you achieved your ideal weight, if you’re not monitoring your heart rate, fitness levels and sleep quality, you’re going to have a harder time detecting the signs of a heart condition or other potential health problem,” he says. “The same thing applies to machine monitoring. If you maximized your Overall Equipment Effectiveness (OEE) and stopped monitoring your equipment, it’ll be that much more difficult to proactively identify abnormalities or anomalies before they become major concerns.”