Floppy Connect

Floppy Connect allows you to replace your floppy drives, which are hard to obtain and can often be unreliable. If you want to implement Floppy Drive Emulator on your shop floor, Shop Floor Automations can help.

Benefits of Installing Floppy Drive Emulators

Though the Floppy Connect hardware doesn’t add memory to your machine, there are so many benefits to the CNC upgrade.

First, Floppy Drive Emulator allows you to refresh legacy machines without replacing them. This upgrades your machine without requiring you to spend thousands of dollars on a new CNC machine.

It also saves you from having to hunt for obsolete storage media. It can be difficult to track down floppy disks but with the Floppy Drive Emulator, you only need a USB stick.

Finally, you can also eliminate proprietary upgrades. Floppy Connect is a small investment compared to having a tech from the machine tool builder evaluate your machine for upgrades.

Types of Floppy Drive Emulators

There are various models of Floppy Drive Emulators available, including:

Floppy Drive Emulator (Universal)

- Eliminate Floppy Disks

- Works with PCs or CNC machinery

- Interface to the existing ribbon cable

- No modification to the equipment needed

- Plugs into the floppy power connector

- Supports 720k/1.44MB capacity IBM

- Support Wired EDM, Mills, Lathes, Robots, & other types of equipment

Haas Floppy Drive Emulator

- Only for Haas machines

- Plug and Play Haas Floppy to USB functions

- Replace old Floppy disks with a USB Flash drive & still maintain Floppy procedures

- Off-the-shelf pricing

- Slide the old floppy drive out of the HAAS & slide in the SFA Floppy Emulator

- Hold the same amount of data on a USB drive that Floppy disk could

- Supports mills, lathes, and tool room CNCs

- Add USB to your old Haas at a low cost

Mazak Floppy Drive Emulator

- Emulates Mazak floppy actions

- Replaces old Floppy disks with a USB stick

- Low-cost Mazak floppy USB solution

- Easily installed hardware

- Handles Mazatrol (CMT) files

- Holds same data amount on a USB drive that floppy disk could

- Add USB to your Mazak at a low cost

- USA support with a toll-free number

Okuma Floppy Drive Emulator

- Only for Okuma machines

- Floppy Disk Drive Core Replacement

- Easy to install and use

- Transfer IGF Files to a USB stick

- Holds the same amount of data on a USB stick that Floppy disk does

If you are trying to decide what Floppy Drive Emulator is right for your shop floor, Shop Floor Automations can help!

Contact Shop Floor Automations for help choosing and installing Floppy Drive Emulator!

If you want to eliminate floppy drives at your facility with Floppy Drive Emulator, contact Shop Floor Automation. We’ve worked with countless clients to improve their shop floor efficiencies and we can help you do the same by installing Floppy Drive Emulator in your machines. Contact us today at (619) 461-4000 to request service today!

To learn more about the Floppy Drive Emulator and the other hardware that we offer, visit us on the web at Shop Floor Automation.

Do you need to connect your Fadal machines? With USB to Fadal, you can not only achieve Fadal file transfers but also increase program storage and streamline loading. That means upgrading your shop without buying expensive new equipment. Regardless of your number of machines, types of machines, or the types of controls, Shop Floor Automations has you covered.

Do you need to connect your Fadal machines? With USB to Fadal, you can not only achieve Fadal file transfers but also increase program storage and streamline loading. That means upgrading your shop without buying expensive new equipment. Regardless of your number of machines, types of machines, or the types of controls, Shop Floor Automations has you covered.

Staying ahead of the competition is essential in today’s competitive environment and updating your shop floor equipment is the way to do that. If you want to eliminate old technology on your CNC machines without having to buy new machines, the USB Connect series can help. With USB Connect, you can increase program storage, drip-feed to CNCs, and store large part programs.

Staying ahead of the competition is essential in today’s competitive environment and updating your shop floor equipment is the way to do that. If you want to eliminate old technology on your CNC machines without having to buy new machines, the USB Connect series can help. With USB Connect, you can increase program storage, drip-feed to CNCs, and store large part programs. Are you contemplating whether you should implement machine monitoring on your shop floor? With machine monitoring from Scytec DataXchange and the help of Shop Floor Automations, you can really take your operations to the next level.

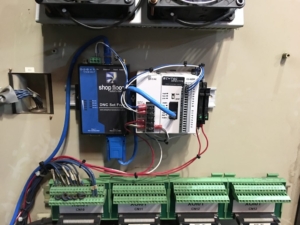

Are you contemplating whether you should implement machine monitoring on your shop floor? With machine monitoring from Scytec DataXchange and the help of Shop Floor Automations, you can really take your operations to the next level. If you are utilizing Scytec DataXchange, you may need to implement hardware with your shop floor equipment. That is where the Status Relay Controller comes into play. This device comes in two versions, SRC Standard and SRC Extended. Shop Floor Automations can help you determine which is right for your shop floor equipment.

If you are utilizing Scytec DataXchange, you may need to implement hardware with your shop floor equipment. That is where the Status Relay Controller comes into play. This device comes in two versions, SRC Standard and SRC Extended. Shop Floor Automations can help you determine which is right for your shop floor equipment.