The Portable USB Connect

If you are looking for a way to improve your shop floor efficiency and eliminate outdated technology on your CNC machines, USB Connect is a great tool. By adding USB to your CNC machine, you can increase program storage and breathe new life into legacy equipment. The great news about USB Connect is that there are several models available, including USB Connect Portable.

What is the USB Connect Portable?

USB Connect Portable is as the name suggests, an easy-to-use, portable version of USB Connect. This communication device comes with DNC firmware and can increase your CNC memory, allowing you to drip feed to almost any CNC Machine. In addition, USB Connect Portable offers the following features:

- Rugged aluminum enclosure with 4 line LCD display

- Portable DNC box with USB directory listing drip-feed operation

- Mid-tape start with search function

- Software, Hardware & Xmodem flow control

- End of block character control & optional delay

- Start/End of transmission character

- Comes complete with cable, USB stick and power supply

What are the technical specs of the Portable USB Connect

For those wondering what the technical specs of Portable USB Connect are, you will not be disappointed. From high Baud Rates and a 4 Line Display, USB Connect Portable has what you need, including:

- Protocols Supported: Xon/Xoff, software handshaking, RTS/CTS hardware handshaking & X-modem

- Supports drip-feed for the above Protocols (if CNC has function active)

- Baud Rates: 1200 – 115,200 supported

- Configurable Data/Parity/Stop Bits

- Includes 4 Line Display & AC Power Supply

- Optional FANUC Power cable can be used for FANUC controls

- Also supports Fadal X-modem/Fadal file transfers and Haas X-modem

- Includes Thumb Drive (can use any brand/size)

- Mid-tape restart

- Connects to RS232 serial port on CNC & no special software required

- Configurable Line Delay & EOB CR/LF

- 1 Year Warranty with free phone Support for device

- Quick Setup Guide & Complete Operation Manual

- Compared to the USB Connect Pendant, it saves four hours not needed for installation & does not need to be dedicated to one machine

Contact Shop Floor Automations for help implementing USB Connect Portable today!

With over years of experience, you can trust the skilled team at Shop Floor Automations to help you implement USB Connect Portable. This communication device is great for loading and saving programs from your CNC memory and can be used to drip-feed to almost any CNC machine. With USB Connect Portable, you can improve your shop floor efficiency and your bottom line. Give us a call today at (619) 461-4000 to discuss the process and cost to implement USB Connect Portable in your facility.

To learn more about the software and hardware solutions we offer to improve your shop floor efficiency, visit us on the web at Shop Floor Automations.

If you need manufacturing software in Irvine CA, Shop Floor Automations has you covered. Whether you are looking for machine monitoring software like Predator MDC, DNC Software or CNC Editor Software, we have what you need to help improve your shop floor efficiency.

If you need manufacturing software in Irvine CA, Shop Floor Automations has you covered. Whether you are looking for machine monitoring software like Predator MDC, DNC Software or CNC Editor Software, we have what you need to help improve your shop floor efficiency. If you want to take your shop floor efficiency to the next level, manufacturing software is what you need to do it. With manufacturing software in San Diego CA, you can automate your shop floor, reduce downtime, and improve overall productivity and efficiency. Thankfully, Shop Floor Automations is here to be your partner in manufacturing software. We have been installing manufacturing software in San Diego CA for years and would be happy to help you out. If you aren’t sure what type of manufacturing software in San Diego CA is right for your facility, keep reading to learn more!

If you want to take your shop floor efficiency to the next level, manufacturing software is what you need to do it. With manufacturing software in San Diego CA, you can automate your shop floor, reduce downtime, and improve overall productivity and efficiency. Thankfully, Shop Floor Automations is here to be your partner in manufacturing software. We have been installing manufacturing software in San Diego CA for years and would be happy to help you out. If you aren’t sure what type of manufacturing software in San Diego CA is right for your facility, keep reading to learn more! In today’s business environment, it is important that you do everything possible to improve shop floor efficiency. Companies and consumers are often sourcing materials and products by the cheapest bid and if you’re inefficient, you might be charging more than you need, which is costing you business to the lowest bidder.

In today’s business environment, it is important that you do everything possible to improve shop floor efficiency. Companies and consumers are often sourcing materials and products by the cheapest bid and if you’re inefficient, you might be charging more than you need, which is costing you business to the lowest bidder. When you need to load and save programs from your CNC and drip-feed to CNC machines, you need USB Connect Pendant. At Shop Floor Automations, we are proud to offer USB to CNC in Dallas TX. Whether you are simply looking to boost overall shop efficiency or have specific drip-feed needs, USB to CNC in Dallas TX can help.

When you need to load and save programs from your CNC and drip-feed to CNC machines, you need USB Connect Pendant. At Shop Floor Automations, we are proud to offer USB to CNC in Dallas TX. Whether you are simply looking to boost overall shop efficiency or have specific drip-feed needs, USB to CNC in Dallas TX can help. Are you trying to figure out how to transfer programs to your Haas CNCs? Many clients have experienced problems loading and saving programs to the CNCs with Windows 10 and don’t know where to get help. Shop Floor Automations is your resource to connect any version of the Haas CNC controller.

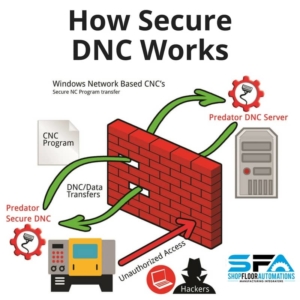

Are you trying to figure out how to transfer programs to your Haas CNCs? Many clients have experienced problems loading and saving programs to the CNCs with Windows 10 and don’t know where to get help. Shop Floor Automations is your resource to connect any version of the Haas CNC controller. Are you trying to figure out how to run DNC software on Windows Server OS? While most customers have to leave the computer unlocked, logged in with a Windows Users to run their DNC software, Predator Software has a unique feature in the application to run as Windows Service.

Are you trying to figure out how to run DNC software on Windows Server OS? While most customers have to leave the computer unlocked, logged in with a Windows Users to run their DNC software, Predator Software has a unique feature in the application to run as Windows Service.

If you are considering installing DNC software at your facility to improve your shop floor efficiency, Shop Floor Automations can help!. Some clients are unsure how operators will interfact with the solution and want to make sure the product is accepted and a good fit. To make sure our solution meets your DNC communication needs we provide a free 30-day trial so you can see the benefits of DNC software first-hand.

If you are considering installing DNC software at your facility to improve your shop floor efficiency, Shop Floor Automations can help!. Some clients are unsure how operators will interfact with the solution and want to make sure the product is accepted and a good fit. To make sure our solution meets your DNC communication needs we provide a free 30-day trial so you can see the benefits of DNC software first-hand.