The following is an archived copy of our Fall 2018 newsletter.

The following is an archived copy of our Fall 2018 newsletter.

Decisions to make for Q4

Fall has begun, and before you know it, Winter will be here. Then, surprise, it’s suddenly Q1. Where did all that time go?!

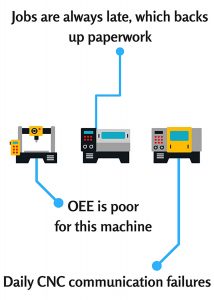

Take a moment to think if you have any of the following issues on your shop floor:

-

- CNC communication failures?

- Old revisions running on machines, with programs floating all over the shop floor?

- Still using a CNC floppy drive instead of USB?

- Old cabling causing too much of a hassle?

Check out DNC software combined with shop floor hardware from Shop Floor Automations. These investments are more affordable than you would assume, and the ROI is exceptional!

If excessive downtime is a concern, scroll to the bottom of this newsletter for information about running a machine monitoring trial!

Want even more info on DNC and hardware? Check out articles about our solutions in publications such as Modern Machine Shop, Moldmaking Technology, CNC West, MFG News & more –

What is your OEE?

If you do not know your true rate of utilization, how can you truly be on the path to improved productivity?

Ask us about a machine monitoring trial! It’s affordable, flexible and illuminating on how productive your equipment really is.

Request info on a DataXchange Machine Monitoring trial

Call (877) 611-5825 for more info!

The following is an archived copy of our Fall 2018 newsletter.

The following is an archived copy of our Fall 2018 newsletter. As American manufacturing grows, efficient machining is key. SFA is often asked about secure and quick CNC to PC communication. Here, we take a look at CNC remote request procedures.

As American manufacturing grows, efficient machining is key. SFA is often asked about secure and quick CNC to PC communication. Here, we take a look at CNC remote request procedures. “Revision control is the management of modifications done to software applications, sites, documents or any set of information,”

“Revision control is the management of modifications done to software applications, sites, documents or any set of information,” Before retiring from

Before retiring from  Manufacturing technology changes each day. Companies want more innovative ways to increase productivity through machine automation. A wireless shop floor is one avenue to pursue.

Manufacturing technology changes each day. Companies want more innovative ways to increase productivity through machine automation. A wireless shop floor is one avenue to pursue. In this Legacy Blog, Shop Floor Automations thanks these digital publications for sharing our recent news about DNC software, machine monitoring, hardware, and more:

In this Legacy Blog, Shop Floor Automations thanks these digital publications for sharing our recent news about DNC software, machine monitoring, hardware, and more:

When working production on a manufacturing shop floor, productivity issues happen. Nothing is perfect – this includes your employees and equipment.

When working production on a manufacturing shop floor, productivity issues happen. Nothing is perfect – this includes your employees and equipment. Unplanned downtime and the impact on production are common aggravation factors in manufacturing jobs. New manufacturing software on your shop floor in 2018 could help with this stress.

Unplanned downtime and the impact on production are common aggravation factors in manufacturing jobs. New manufacturing software on your shop floor in 2018 could help with this stress. As a manufacturer, you have a lot of daily concerns, such as downtime and productivity. Is your manufacturing ROI an issue that is falling to the wayside?

As a manufacturer, you have a lot of daily concerns, such as downtime and productivity. Is your manufacturing ROI an issue that is falling to the wayside?