3 Strategic Ways to Reallocate Excess Budget

As manufacturers across North America spend time reflecting, strategizing, planning and budgeting for the year ahead, leaders are debating how to defend against disruption and strengthen their offense. It’s a great time to ask yourself: How did my department stay on track with its goals? In what ways was my team successful? Where did we go astray, and why? Did we “make bold investments in talent, technology, and innovation?” Forbes stresses that those manufacturers who made the right decisions post-crisis can be on the road to major rewards.

Leverage the Present for Future Success

The good news is that you don’t need to limit your action to these responses to just 2023. There are three strategic ways you can reallocate excess budget now to get a head start on your future goals and positive economic indicators, while minimizing what Deloitte refers to as “historic labor and supply challenges.”

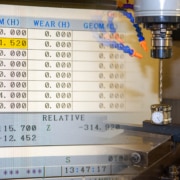

- Invest in your team. What opportunities have your shop floor teams identified for efficiency gains? Are you looking to reduce the amount of NC program transfer time and effort to CNCs? Is the ongoing maintenance and changing of RS232 serial cabling consuming already-limited resources? By factoring in valuable team input into your automation strategy early and leaning on your preferred manufacturing integrator for execution, you can invigorate crews while making inroads to continuous improvement initiatives.

- Lock in your support and services. Workforce limitations can impede project timelines, particularly as more and more companies are turning toward automation to complement skilled labor. By securing manufacturing integration support and services prior to year end, you can rest assured that your priorities will stay the course – and faster than your competition.

- Map out a phased approach. If you’re looking to increase communication on the shop floor or reduce programming waste in the new year, there are tasks that can be completed prior to year end for an efficient and effective start. The piloting of a few machines or setting up of a network connection can be relatively smaller undertakings that can position your organization for success in the year to come. Robert Jackson, a manufacturing engineer at artificial lift manufacturer Flowco, decided on a phased approach to bring on Predator DNC with Shop Floor Automations. “We didn’t have a network at the time, so we chose to start with four machines for the first phase of our implementation,” explained Jackson. It took two days to set up the network wirelessly. Flowco then added 12 machines. Six months later, the company had hooked up 11 more machines to the Predator DNC network and are expecting to do the same to five more in the near future as a result of significant growth.

While next year can hold a lot of promise for companies making the right moves, Deloitte predicts that “supply chain issues including sourcing bottlenecks, global logistics backlogs, cost pressures, and cyberattacks will likely remain critical challenges in 2023.” The remaining part of 2022 can set the stage for success if planned out strategically. Contact SFA for help designing a budget to fit your strategic automation plans for 2023 today.