What is Predator Secure DNC?

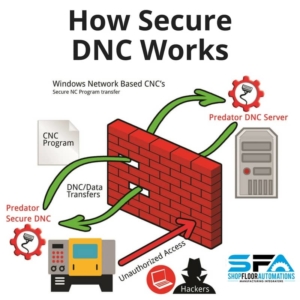

In short, Predator Secure DNC is essentially a tool that allows you to securely transfer files to and from CNC machines through firewalls. This is important for businesses that have strict network security that would otherwise hinder the transfer of a file. This Windows-based application is a headless Windows product that can be installed on any shop equipment.

The Benefits of Installing Predator Secure DNC

There are many benefits associated with installing Predator Secure DNC. Unlike other applications that contain restrictions, you can integrate Predator Secure DNC on any type of legacy equipment. It also boasts transparent CNC network security and can reduce the cost for upgrades that would otherwise be required with older equipment.

Another benefit of Predator Secure DNC is that it has a minimal footprint. The standardized communication protocol’s PSDNC.EXE is just 228k and only consumes 1750k of memory while it’s running. While it will create an ASC II log file for troubleshooting and one backup log file, these are capped at just 120k so they shouldn’t take up too much bandwidth.

Last but not least, Predator Secure DNC uses just a standard TCP/IP protocol and is actually included with Predator DNC and DNC Enterprise. That means there is no additional cost for the security application, aside from any minimal expenses incurred to hire a shop floor automation specialist like Shop Floor Automations to implement it.

Predator Secure DNC is Supported by Numerous Operating Systems

Predator Secure DNC is designed for Windows systems. Predator DNC v.11 supports many client operating systems, including Windows 7, 8, 9, Vista, XP, ME, 98, and 95. The variety of operating system compatibility makes Predator Secure DNC a great option for those operating legacy systems and older equipment.

In addition, Predator Secure DNC also supports different server operating systems, including Windows 2016 Server, Windows 2012 Server, Windows 2008 Server, Windows 2003 Server, Windows 2000 Server, and Windows NT v4.0 Server.

Let Shop Floor Automations Bridge the Gap between Your Shop Floor and IT Department!

Many machines can be connected to a corporate network, but there are often risks associated with that. At Shop Floor Automations, we can help bridge the gap between the shop floor and your IT Department by implementing a standard across all your equipment. By installing Predator Secure DNC you can let your IT Department focus on fighting viruses and hackers instead of dealing with domains, home groups, workgroups, NETBUI, unsupported operating systems, and more.

With over years of experience working to improve shop floor efficiencies, Shop Floor Automations can implement Predator Secure DNC in a timely manner. Contact us today at (619) 461-4000 to get started!

Keeping your shop running efficiently and minimizing downtime is essential in today’s competitive landscape. Thankfully, DNC software allows you to link all of your CNC programs, offsets, and machine parameters on a single network. There are several options out there for DNC software, but Predator DNC far exceeds what free software alternatives are able to provide.

Keeping your shop running efficiently and minimizing downtime is essential in today’s competitive landscape. Thankfully, DNC software allows you to link all of your CNC programs, offsets, and machine parameters on a single network. There are several options out there for DNC software, but Predator DNC far exceeds what free software alternatives are able to provide. Since , Shop Floor Automations has helped countless clients automate their shop equipment and improve their overall efficiencies. With vast expertise and hardware solutions for over 80 brands and hundreds of controllers, you can trust Shop Floor Automations with your machine automation and monitoring. Based in La Mesa, California, we have the hardware, software, and expertise necessary to help take your shop floor equipment to the next level.

Since , Shop Floor Automations has helped countless clients automate their shop equipment and improve their overall efficiencies. With vast expertise and hardware solutions for over 80 brands and hundreds of controllers, you can trust Shop Floor Automations with your machine automation and monitoring. Based in La Mesa, California, we have the hardware, software, and expertise necessary to help take your shop floor equipment to the next level.