DNC software for CNC communication

Shop Floor Automations has been providing DNC software to communicate to CNC machines since 1998. We provide two leading software product lines: Predator Software and Ascendant Technologies.

Most companies have methods to deliver files to machines, but are limited to using floppy disks, USB sticks, PCMCIA cards, and tape readers—or even manual typing. Theses methods use several hours to load programs, but offer no revision control, management of proven or released files, or traceability.

With our solutions, we can implement a product that improves productivity and tracks every upload, download or drip-feed to the CNC, while decreasing the time it takes to load programs. Every minute on the shop floor counts, and if we can save you 5 minutes a day, your new system could be paid for in months.

We offer wired and wireless solutions, personalized to meet your specific needs. Want to learn more? Visit us at shopfloorautomations.com or call us at 877-611-5825. More info on our DNC Solutions:

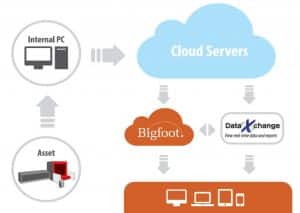

Manage your CNC programs, machine parameters, & offsets. Enjoy a wide range of CNC communication options from your Predator PCs for drip-feeding, downloading, & bi-directional communication. Upload via parallel, RS232, RS422 Ethernet, & wireless Ethernet for thousands of CNC machines. With Microsoft Office & Windows Explorer-compatible user interface (Windows 10 O/S supported), use familiar features for drag & drop, cut, copy, paste, shortcut menus, object-based menus, toolbars, tool tips, & available online help.

Improve CNC revision control while using existing ERP & MES bar-coded paperwork. Eliminate time wasted walking back & forth between your CNC & PC with a Remote Request function. Consider a 32-Bit, Multi-thread, Multi-tasking, Open-Architecture DNC Software solution that works wired & wirelessly.

Simplify operations with one network for all of your CNC machines, Robots, PLCs, & part makers, grouped by building or cell.

We offer the following DNC Communication solutions: Predator DNC, Ascendant extremeDNC, Predator TouchHMI, and Predator EditLock. We also have many pieces of hardware to help your shop floor achieve wireless DNC.

Production Machining Magazine

Production Machining Magazine MoldMaking Technology magazine

MoldMaking Technology magazine Shop Floor Automations (SFA), a provider of software for the manufacturing shop floor, installed Predator’s version 9.0.16 through the end of 2013 while beta testing version 10.0 of Predator DNC Software and Editor.

Shop Floor Automations (SFA), a provider of software for the manufacturing shop floor, installed Predator’s version 9.0.16 through the end of 2013 while beta testing version 10.0 of Predator DNC Software and Editor. Shop Floor Automations 2014

Shop Floor Automations 2014 Greg Mercurio in Manufacturing Engineering

Greg Mercurio in Manufacturing Engineering Production Machining – August 2013

Production Machining – August 2013 Machine Monitoring and Data Collection ad

Machine Monitoring and Data Collection ad