CAD CAM Software Resources

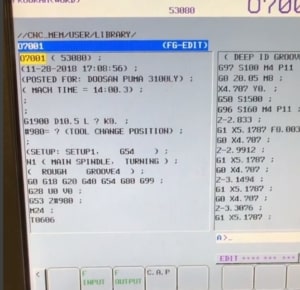

Photo credit to DixiePrecision on Instagram

CAD CAM software is a powerful shop floor tool. There is a long-term problem most users don’t consider. What happens to the programs that the software produces?

“CAD CAM makes these beautiful models, then it produces G-code. What’s going to happen to it?” This question was posed by a Shop Floor Automations (SFA) spokesperson on the Manufacturing Engineering podcast.

“It’s going to go onto these USB sticks. You have all of these portable media going around the shop floor, or it’s sitting on someone’s computer.”

Read more below!

The issue with these storage methods? “The incorrect revision is going to run – nobody wants that. It’s going to waste material and man-hours.”

Here are the top tools that SFA recommends that you combine and integrate into your CAD CAM routine to prevent issues like this from happening:

Solution 1 – DNC Software

- Organizes and stores thousands of programs

- Communicates the code to the machines

- Revision control

- Ideal for larger shops

- The best option for those changing part programs often

- Helps to stream/drip-feed larger programs

- Remote request saves time for machinists

- Secure DNC for older, Windows-based machines

Solution 2 – Hardware

- Economic option for smaller shops running the same program for long periods of time

- No back and forth from computer to CNC, or having to carry around a laptop

- Better option versus proprietary, expensive memory upgrades

- Modernize machines by turning RS232 ports into USB ports

- Replace floppy disks with USB sticks for improved, modern program storage

- Wireless helps those who like to move machines around the shop floor with less downtime

- There are also specific Cabling and Ethernet solutions for customers who prefer it

Solution 3 – Machine Monitoring

- Make sure machines are running

- Programs won’t work for a machine that is down

- Real-time data to help locate sources of downtime

- Increased uptime leads to better machine capacity

- Less downtime means more productivity

Want more information? Let us know what kind of CAD CAM you have. We can even integrate with ERP and CMMS software! Fill out a contact form or call (877) 611-5825