Become a Cloud technology MFG Adapter

The manufacturing industry is slowly becoming a younger job field. The Manufacturing Institute states that 3.5 Million manufacturing jobs will become available within the next decade due to Millions of baby boomers retiring from the workforce in the near future. There are also new jobs created because of organic business growth to take into consideration. These new jobs will definitely be filled by a younger generation that embraces Cloud technology in their daily lives.

With a new generation coming into the manufacturing landscape, which contributes over $2 Trillion dollars to the American economy each year (according to the National Association of Manufacturers), they are going to understand that any time or production lost on their shop floor will make a huge impact on many people. This is why it is no surprise that 80 percent of large North American companies have implemented or are planning to adopt Cloud services, as the workforce gets younger.

“On the shop floor, manufacturers are aggregating data to gain insight on machine and equipment performance, part tracking, and even how to optimize [the] shop floor layout,” Kathy Webster said, who is the Media Communications Manager for The Association of Manufacturing Technology (AMT). “This is especially true as pressure mounts for manufacturers to bring products to market more quickly.”

“Cloud solutions like these are often quick to roll out and easy to customize,” Kathy continues. “Many also offer 24/7 support, meaning less stress on a company’s IT staff. They are easy to access at any time from anywhere, making them a natural fit for collaboration on supply chain, distribution, and service.”

Aside from the benefits that Cloud software and applications can have on your shop floor, these solutions also tend to be more economical, too. At trade shows that Shop Floor Automations attends, guests are astounded that there is a machine monitoring option that costs a mere $45 per month, per machine!

Want more information on how to embrace IIoT on your shop floor? Call us at (877) 611-5825 or fill out a contact form, so we can get back to you.

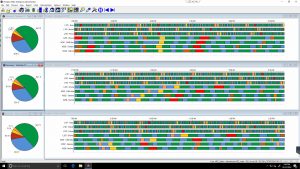

In February of 2016, MoldMaking Technology published an article about our machine monitoring solutions through Scytec DataXchange. “Scytec DataXchange software from Shop Floor Automations (SFA) is a machine monitoring software that provides detailed data collection and real-time reporting on a dashboard, enabling users to instantly track productivity, and plan for increased efficiency and time savings on the shop floor.”

In February of 2016, MoldMaking Technology published an article about our machine monitoring solutions through Scytec DataXchange. “Scytec DataXchange software from Shop Floor Automations (SFA) is a machine monitoring software that provides detailed data collection and real-time reporting on a dashboard, enabling users to instantly track productivity, and plan for increased efficiency and time savings on the shop floor.”

The test utilized a steel-framed test rig, made by OSML’s Dan Hendricks and his daughter in a 14-hour project, to hold the object in place for a test of the rocket’s control valves and fluid systems. OSML also hosted a launch party at their lab for those who could not make it to the launch site, when Vulcan1 went airborne.

The test utilized a steel-framed test rig, made by OSML’s Dan Hendricks and his daughter in a 14-hour project, to hold the object in place for a test of the rocket’s control valves and fluid systems. OSML also hosted a launch party at their lab for those who could not make it to the launch site, when Vulcan1 went airborne.