DNC Manufacturing: Automate CNC machines with DNC software

View this brief video for more information on how we can help automate your CNC machine.

Via our Software solutions page:

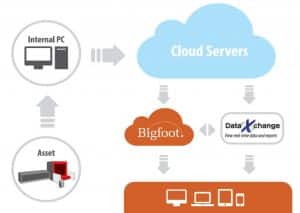

Shop Floor Automations (SFA) uses the top software brands in the manufacturing industry to provide and support the best solutions for our customers. They can make your machine shop more efficient using machine monitoring, job scheduling, DNC, document control, CNC editing, and more.

SFA is committed to addressing manufacturing automation needs of customers with individualized solutions. By offering an extensive collection of software and hardware products, they scale automation solutions to customers of any size and range. SFA’s goal is to build lasting partnerships with customers by understanding their specific manufacturing & production needs.

Ascendant Technologies – Manufacturing industry software applications

- eXtremeDNC: Drip-feeding & bi-directional communication with over 1000 CNCs.

- XYZPRO 32 Plus: User friendly G-Code editing & backplotting.

Predator Software – Automate, network, monitor & control your machine shop

- CNC Editor: Shop floor editing, tracking & control.

- DNC: Shop floor connectivity, controls & communication.

- MDC: Data collection of shop floor productivity metrics to improve operations & decisions.

- PDM: SFA helps coordinate & control shop documents plus revisions.

- Tracker: Help for shop floor editing, tracking & control.

Scytec – Data collection to get the most of your machines

- DataXchange: Tools to measure, analyze & improve your shop floor.

MTConnect – SFA utilizes this universal factory floor communication standard to enable the efficient transfer of data between devices & software applications. More info here

Call (877) 611-5825 for more information

The following is an archived copy of the Shop Floor Automations Newsletter – July/August 2014 issue.

The following is an archived copy of the Shop Floor Automations Newsletter – July/August 2014 issue. Production Machining Magazine

Production Machining Magazine MoldMaking Technology magazine

MoldMaking Technology magazine The following is an archived copy of the Shop Floor Automations Newsletter – March/April 2014

The following is an archived copy of the Shop Floor Automations Newsletter – March/April 2014 Shop Floor Automations 2014

Shop Floor Automations 2014