In the January issue of Modern Machine Shop, Josh Davids of DataXchange discusses the difference between two different, popular protocols. MTConnect and OPC UA are compared.

In the January issue of Modern Machine Shop, Josh Davids of DataXchange discusses the difference between two different, popular protocols. MTConnect and OPC UA are compared.

“Although OPC UA and MTConnect are both http-based protocols (which makes them usable on internet-enabled networks), the question why MTConnect exists often arises since OPC UA has been around for a while and has wide support throughout industry,” Davids said.

“If we view machine monitoring at a high level, it’s apparent that MTConnect is best-suited for equipment with standardized functions, such as CNC controls or other equipment that has known capability. OPC UA is generally best-suited for one-off integration projects that use programmable logic controllers (PLCs),” Davids continued. “Another difference is that OPC UA can be a read-write protocol, whereas MTConnect is read-only. Nothing can be written back to the machine.”

There is much more insight on why MTConnect and OPC UA are different in Davids’ contribution piece.

MTConnect versus other protocols

For more information on machine monitoring, DataXchange or MTConnect, please contact us! We are the #1 reseller of DataXchange and we have the distinction of being an MTConnect Institute Roster Member. Call (877) 611-5825 or fill out a contact form.

In the January issue of Modern Machine Shop, Josh Davids of

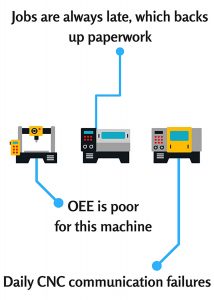

In the January issue of Modern Machine Shop, Josh Davids of  When working production on a manufacturing shop floor, productivity issues happen. Nothing is perfect – this includes your employees and equipment.

When working production on a manufacturing shop floor, productivity issues happen. Nothing is perfect – this includes your employees and equipment. The following is an archived copy of our Shop Floor Automations newsletter from November 2017 focusing on lights-out manufacturing:

The following is an archived copy of our Shop Floor Automations newsletter from November 2017 focusing on lights-out manufacturing: As a manufacturer, you have a lot of daily concerns, such as downtime and productivity. Is your manufacturing ROI an issue that is falling to the wayside?

As a manufacturer, you have a lot of daily concerns, such as downtime and productivity. Is your manufacturing ROI an issue that is falling to the wayside? Manufacturing costs are a pain.

Manufacturing costs are a pain. How does this relate to manufacturing integration solutions & ROI?

How does this relate to manufacturing integration solutions & ROI? Here are the Top 3 ways that new manufacturing technology adopted on the shop floor can benefit your company:

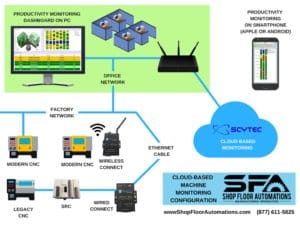

Here are the Top 3 ways that new manufacturing technology adopted on the shop floor can benefit your company: Shop Floor Automations is a big proponent of Cloud tech, especially in terms of the Industrial Internet of Things, or the IIoT. One of our hottest sellers is DataXchange from Scytec, with its $45 per month per machine pricing policy for Cloud-based services. We also realize that secure drip-feeding is a concern of note, as well, in the manufacturing community.

Shop Floor Automations is a big proponent of Cloud tech, especially in terms of the Industrial Internet of Things, or the IIoT. One of our hottest sellers is DataXchange from Scytec, with its $45 per month per machine pricing policy for Cloud-based services. We also realize that secure drip-feeding is a concern of note, as well, in the manufacturing community.