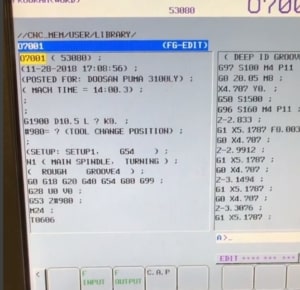

Modernizing your manufacturing equipment is easier and more affordable than you may otherwise assume. Operators love USB to RS232 transfers of machine programs for many reasons.

This CNC upgrade hardware helps machinists save time, it assists with basic program revision control and the devices that perform these actions help increase memory. Also, since these devices are positioned close to the control, it allows the machine to run at its maximum baud rate.

Here are quick videos with easy steps in which to perform USB machine transfers:

- Make sure your package has all of its contents

- Configure your device

- Store your parameters

- See how to receive from the CNC

- Then, you should be ready to go!

The devices come in pendant models that are dedicated to one machine. There is also the popular portable model, which saves machine operators even more time.

Our list of CNC machines that USB Connect hardware is compatible with includes Siemens, Anilam, Bridgeport, Cincinnati, Fadal, FANUC, Haas, Yasnac, Brother machines, Mitsubishi, and others. Special models also perform Mazak and Switchbox functions.

Ready to learn more? Call (877) 611-5825 or fill out a contact form

What is IIoT? Here are the basics about the Industrial Internet of Things.

What is IIoT? Here are the basics about the Industrial Internet of Things. The November/December 2018 SFA email blast was a lean manufacturing newsletter. It was sent to subscribers November 19th, 2018.

The November/December 2018 SFA email blast was a lean manufacturing newsletter. It was sent to subscribers November 19th, 2018.

Want RS232 to USB hardware results before purchasing? Check out this case study with Fredon Corporation!

Want RS232 to USB hardware results before purchasing? Check out this case study with Fredon Corporation! Lean manufacturing is a hot topic these days. It’s more than a buzzword, though. It’s becoming a necessity.

Lean manufacturing is a hot topic these days. It’s more than a buzzword, though. It’s becoming a necessity.