Scytec DataXchange

On-Premise or Cloud-based OEE Monitoring

Machine Monitoring Key Features

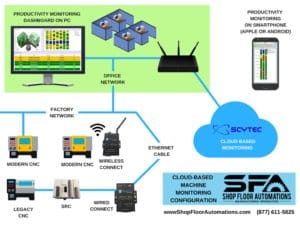

- On-Premise or Cloud-based monitoring solution

- Store data on your server or in a data center

- Track real-time OEE, utilization & more

- Integrate with any ERP or business system

- Unlimited reporting & charting licenses

- Customize dashboards for real-time productivity

- Flexible operator data entry – Windows, iOS & Android

Success Story

Read our Modern Machine Shop piece about how DataXchange through Shop Floor Automations got Tech Manufacturing to achieve high metal removal rates and an instant productivity boost!

Features

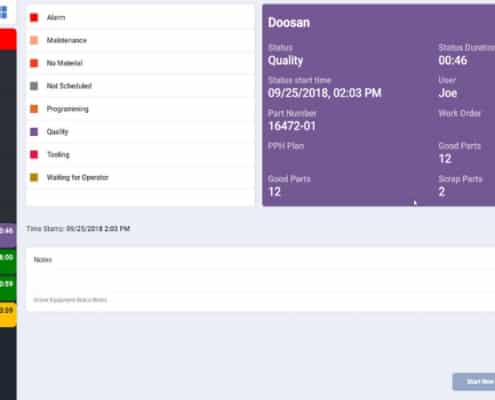

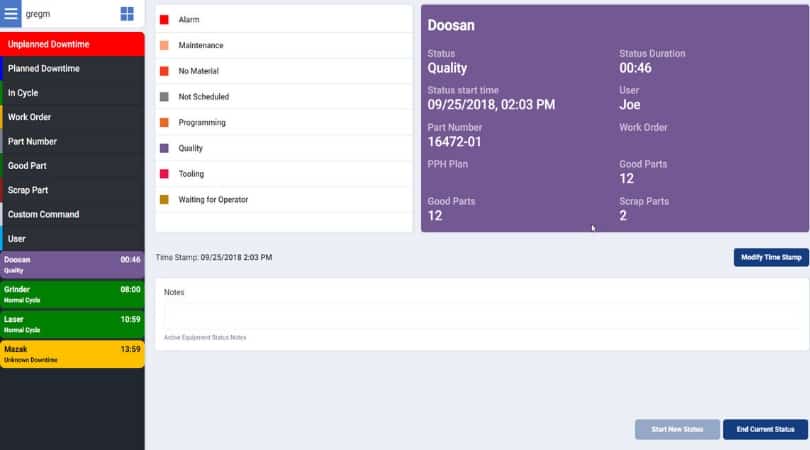

- Real-time overall equipment effectiveness dashboard for manufacturers

- Monitor machine overrides and downtime – remote machine monitoring

- Machine data collection and shop floor data entry for productivity

- Equipment status, reports, and charts for lean MFG

- Mobile monitoring – notifications via text/email

Track multiple types of cycle time

- Track various cycle times, such as spindle and load-to-unload time

- Use hardware adapters with protocols such as MTConnect or FANUC FOCAS

- Report on utilization and efficiency metrics

- Run reports on and compare different sets of cycle time

Want more info, but you’re not ready to request a quote?

Sign up for a machine monitoring webinar!

Overview

Reports and charts that display OEE and IIoT info from Scytec DataXchange help improve machine utilization and minimize downtime. “Collecting data from the machines is one thing, but utilizing the data for actionable results is critical in order to convert manufacturing data into manufacturing intelligence,” Scytec proclaims to customers.

Timelines, equipment status summaries, OEE summaries, trends, downtime Pareto, scrap Pareto, histograms, plots, comparisons, and more can be charted. These charts can be displayed in the real-time dashboard of the program, which includes being able to save group or personalized chart templates, and the ability to export this data to CSV or Excel.

“DataXchange is a Cloud and On-Premise manufacturing machine monitoring system,” Scytec says of their services. With over 15 years of experience in manufacturing, they were able to create this program from scratch.

“Increasing utilization by roughly 30 minutes per machine will cover the cost of the software. How about the gains of knowing when machines are running at a lower feed rate, a program stop, or sitting in feed hold? The software typically pays for itself within the first few days of each month.”

Technology

Read an article from Industry Week about how a mining and dredging equipment company optimized their employees’ time, operation efficiency, and cut costs.

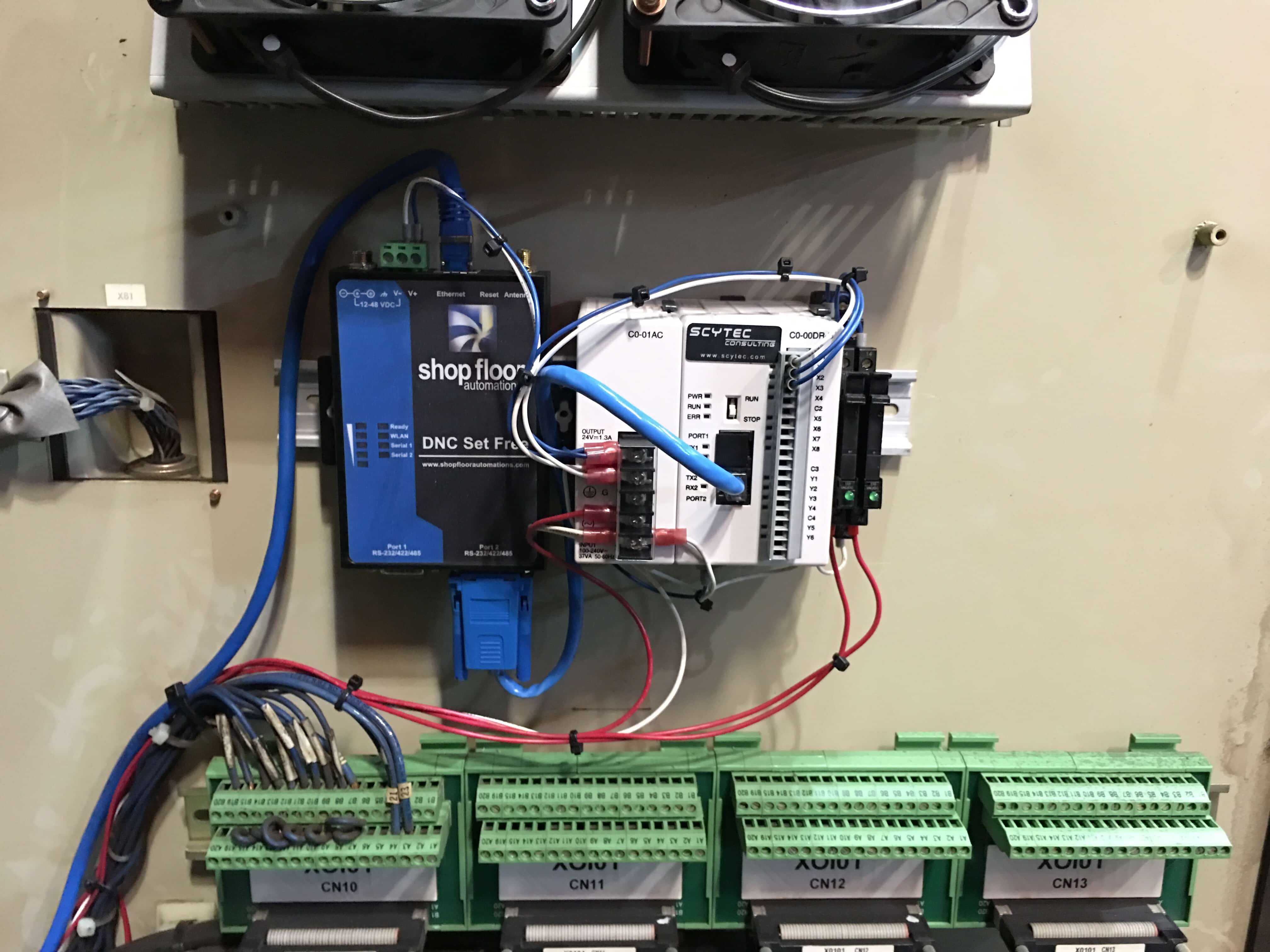

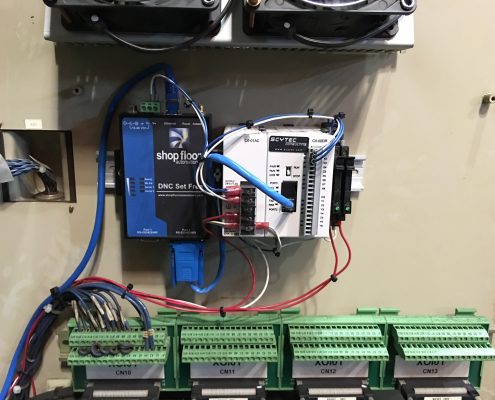

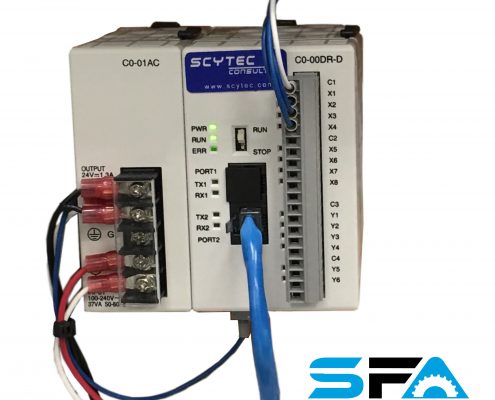

Integrate with Hardware

Using both DataXchange machine monitoring, alongside special hardware that added Ethernet capabilities to older machines, helped one manufacturer increase uptime.

Check Out Our DataXchange Videos

For more information from the #1 reseller of DataXchange, please call (877) 611-5825