What is OEE?

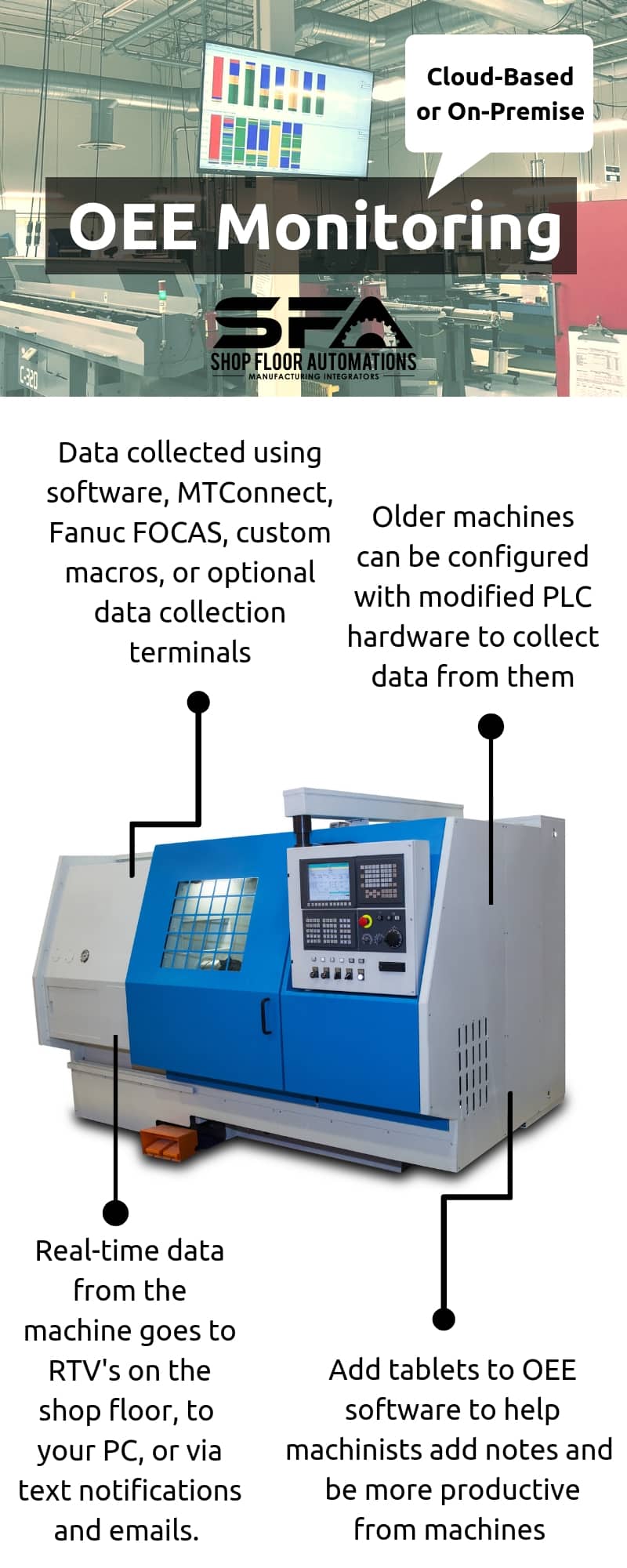

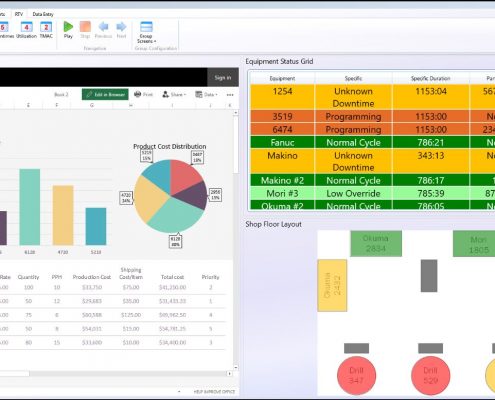

Customers often call asking us for an OEE definition. OEE is overall equipment efficiency, with the data obtained via machine monitoring software. Customers don’t usually know what their numbers are, or they over-estimate how well their machines are actually running.

Knowing your true utilization is about more than increasing machine capacity and profits. Data-driven decision making from machine monitoring also helps to improve the processes of ordering raw material, calculating new hires you are able to make, and more.

Goals customers have such as cycle time reduction, predictive maintenance, and preventative maintenance also are related to OEE improvement. Pursuing OEE also comes with unforeseen benefits of improved shop floor communication and steps towards lean manufacturing.

Customers who don’t have CNC machines had previously assumed they could not be helped because they had different equipment. No doubt about it – fabrication shops, moldmakers and other manufacturers are also part of this quest for better productivity.

Metrics & KPIs

- Automated data collection

- Cycle time

- Scrap time

- Downtime

- Find & fix productivity issues

Downtime Reasons

- Lockout/tagout

- Material needed

- Down for maintenance

- Data to evaluate later to improve processes

Stay Informed

- Notifications show across shop floor via RTVs

- Check from your shop floor PCs

- Email notifications

- Text alerts on your phone

Grab Important Machine Data

What customers say about OEE monitoring

“We have been able to increase our productivity by 25 percent just monitoring the machine utilization.” Derek at Aero Precision

“There was minimal startup cost and it requires little software management on the user end. Benefits are significant increases in machine utilization, better [internal] information flow.” Jerry at Tech Manufacturing LLC

“The company began to measure not just its cycle time and not just the processing of individual parts, but the entire performance of its CNC machines around the clock.” Modern Machine Shop Case Study on machine monitoring