mtconnect protocol solutions

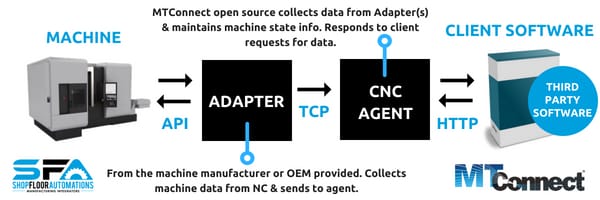

MTConnect is an open, royalty-free, universal factory floor communication standard that is designed specifically for the shop floor environment. The protocol enables efficient transfer of data between devices (such as CNCs) & manufacturing shop floor software applications.

Some users compare it to the “Bluetooth” technology on our smartphones & daily electronic devices. Achieve an open & extensible channel of communication. Plug-and-play interconnectivity between devices, equipment, & systems. MTConnect allows sources to exchange & understand each other’s data – it’s like speaking a common language!

If you want propriety software & solutions, MTConnect is not the right solution. This new standard will bridge your factory shop floor & link you to the Industrial Internet of Things (IIoT).

Think of your equipment. Can it connect, give you real-time data & speak to each other? While some equipment have limitations on data you can grab from it, the protocol allows information to quickly be displayed on dashboards, smartphones, ERP/MRP systems, & other equipment.

Improve shop floor communications & manufacturing productivity on your shop floor without expensive integration, proprietary hardware, custom software, or outrageous licensing costs.

Shop Floor Automations is on the MTConnect Institute Roster via the Technical Advisory Group (TAG). Let’s start the conversation!

Latest MTConnect News

Version 1.6.0 of the protocol has been released. Updates on overview, fundamentals, devices, cutting tools, interfaces, and more! We also invite you to call us for more info at (877) 611-5825

As a member of TAG, we are part of the development and review of standards for the protocol. Many machine tool builders listed below are part of the ongoing development and support for this standard.

We strongly recommend you purchase machines with this standard for future automation support. This standardized solution has the capability to work with many eligible machines – even monitoring multiple factories in real-time!

SFA can facilitate an MTConnect Adapter for these controls:

- MtConnect for Citizen – SFA can provide and install an adapter for your M7/M700 controls.

- MTConnect for Doosan – SFA can provide and install the adapter for these machines/controls.

- MTConnect for Fanuc – Now available from Fanuc direct.

- MTConnect for Haas – The controller must have Ethernet and have the latest firmware of 16.05B for mills and L09.06A for lathes. SFA can provide and install the adapter on your controller. Next Gen controllers are directly supported by our software solutions natively.

- MTConnect for Makino – An adapter is available on Pro5, ProF, ProP and Pro3 controllers that are based on Fanuc FS16iMA or newer.

- MTConnect for Mazak – Mazak is actively supporting the protocol as a way to provide complete manufacturing solutions. This includes having more than 200 of their machines prepped to accept the adapter before they are shipped, as well as adding additional adapters for existing Mazak equipment in the field.

- MTConnect for Mitsubishi machines – SFA can provide and install the adapter for your controller.

- MTConnect for Okuma – Okuma machine tools are protocol-ready. The Okuma THINC-OSP Control is already configured for plug-and-play interconnectivity between devices, equipment, and systems on both your shop floor and front office. These controls support v1.2 compliant Adapters. OSP Control types P100 Type II, P200, P200A, P300, & P300S

- MTConnect for Siemens – SFA can provide and install the adapter for your 840D controller.

An MTConnect Adapter comes pre-installed on certain controls:

- MTConnect for DMG Mori Seki via their standard communication protocol. As of June 1st, 2013, all new DMG / MORI SEIKI machines equipped with MAPPS control come installed with a V1.1 compliant Adapter. We recommend you contact DMG to have the latest MTConnect Software installed.

Supports the standard communication protocol:

- Allen-Bradley

- Bosch Rexroth

- Balluff

- ControlLogix

- C.R. Onsrud

- Doosan

- Fagor

- FINS

- GF Agie Charmilles

- Gleason

- Hardinge

- Hurco

- Mag

- Mitsubishi

- NUM

- Siemens

- Sodick

- Southwestern Industries

Other Standards?

MTConnect-B2MML is a companion specification to ensure interoperability and consistency between the protocol’s specifications and the B2MML implementation of ISA95.

MTConnect-OPC UA is a set of companion specifications to ensure interoperability and consistency between protocol specifications and the OPC Unified Architecture (UA) specifications.

If you have legacy CNC machines, we can often add hardware with MTConnect to continue to standardize on this protocol if desired. However, the cost to add this equipment may not expose additional data points to justify this standard. We also specialize in solutions for fabrication equipment, robots, assembly lines, and other factory floor equipment.

If you want to learn more, please call (877) 611-5825

Scytec DataXchange Software

- Low-cost, simple way to monitor shop floor equipment from anywhere with Internet access

- Machine monitoring as low as $45 per month per machine

- Collect real-time shop floor data with no servers to maintain

- Works with any CNC controller type or equipment

- Cloud or On-Premise Solutions

Predator MDC Software

- Real-time machine monitoring software

- Automatically collects, reports, charts, and processes manufacturing data

- Data evaluated includes OEE, cycle time, idle time, setup time, tear down time, downtime & more