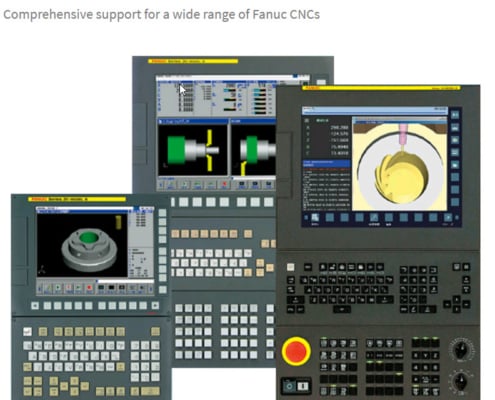

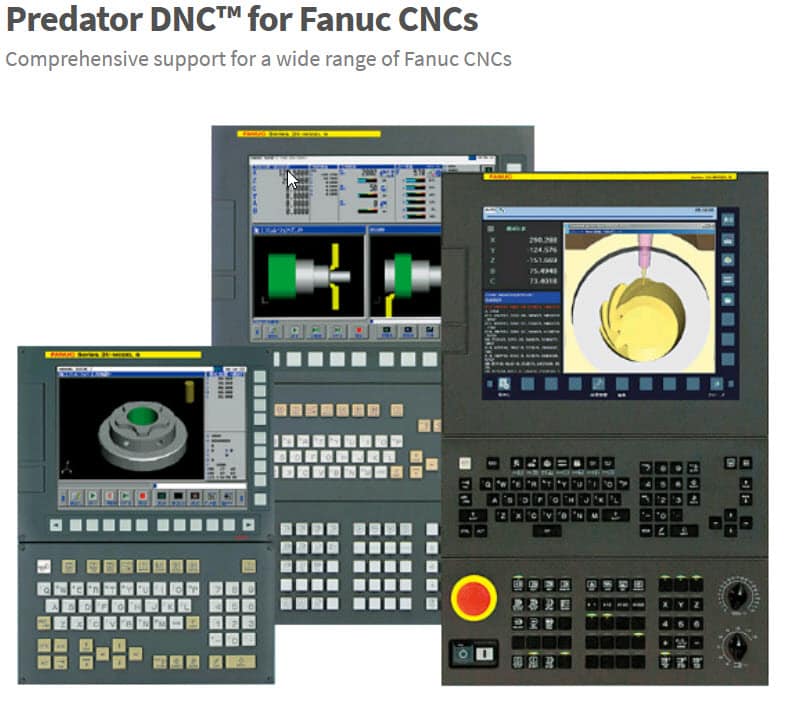

Predator DNC software

DNC Software Key Features

- Network all CNCs, EDMs, PLCs, & Robots with singular DNC package

- Eliminates walking to/from CNC control & PC

- Supports CMMC 2.0 compliance

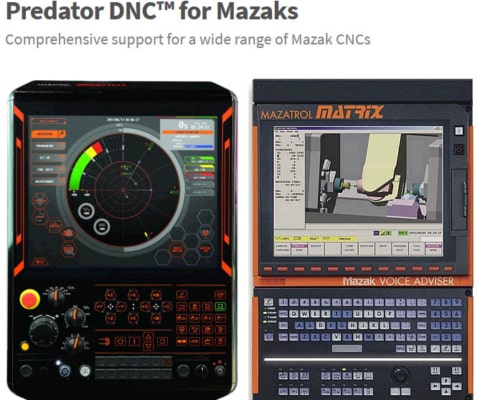

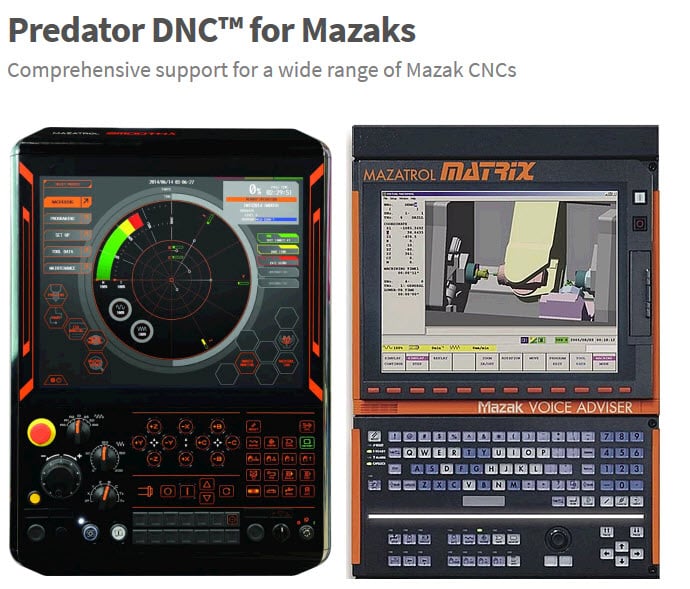

- Mazatrol (CMT), Xmodem, Okuma B & more

- Send, receive or drip-feed to 4000+ devices

- Upload & download Wirelessly, Wired, via Ethernet, & USB

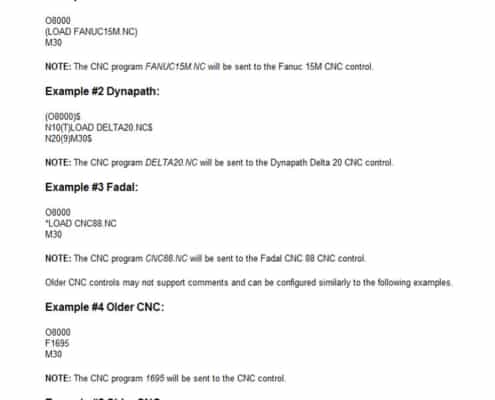

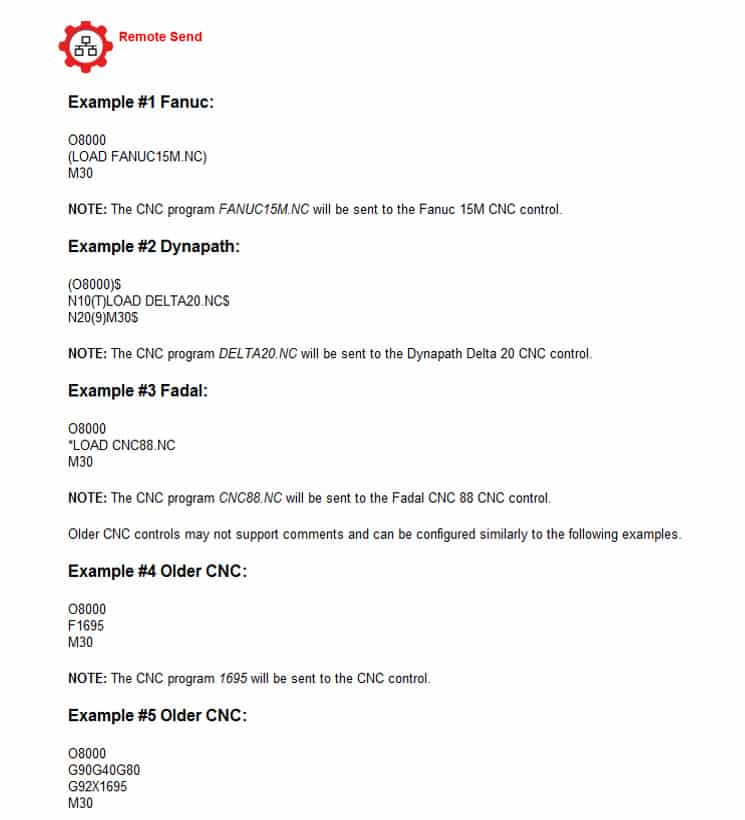

- CNC Revision Control & Remote Request

Save Time on Data Transfers

Read our article in Modern Machine Shop

Flowco Lifts CNC Program Productivity to New Heights

Features

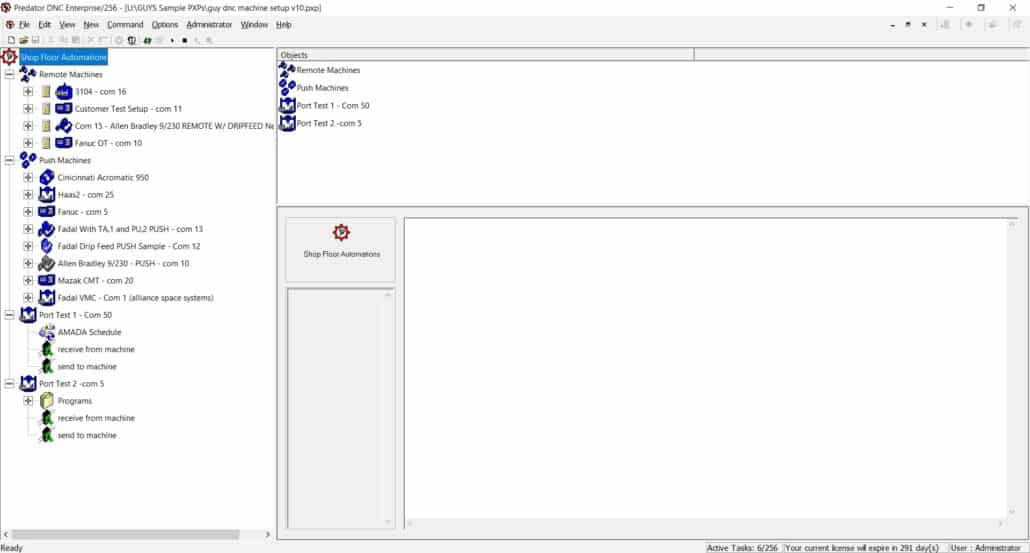

- CNC networking of all machines with one solution

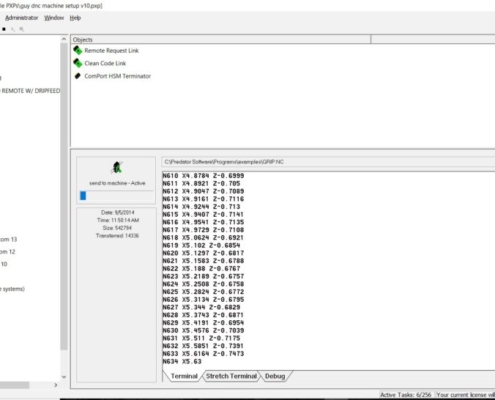

- Drip-feed, upload and download all DNC programs

- Mid-program restart after tool breaks remotely or at PC

- Send, receive offsets, variables and registers

- Improve CNC part program and CNC variable management

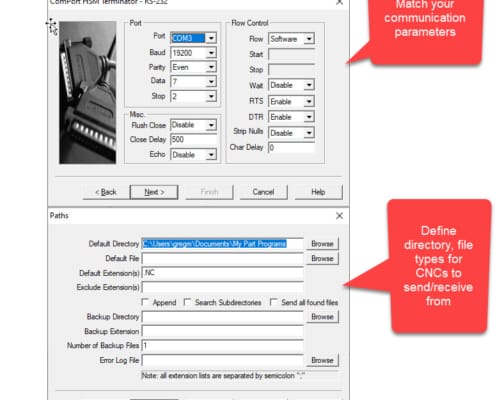

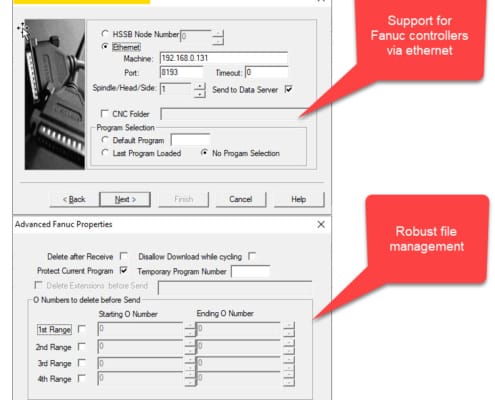

- Connect wirelessly, RS-232, Ethernet

- Eliminate walking back and forth; works from your CNC

- Remotely see directory listing using RS-232 serial CNC

- Streamline the processes between your CNCs

- Add Touch HMI for customize operator screens

- Automate methods for transfers using bar code readers

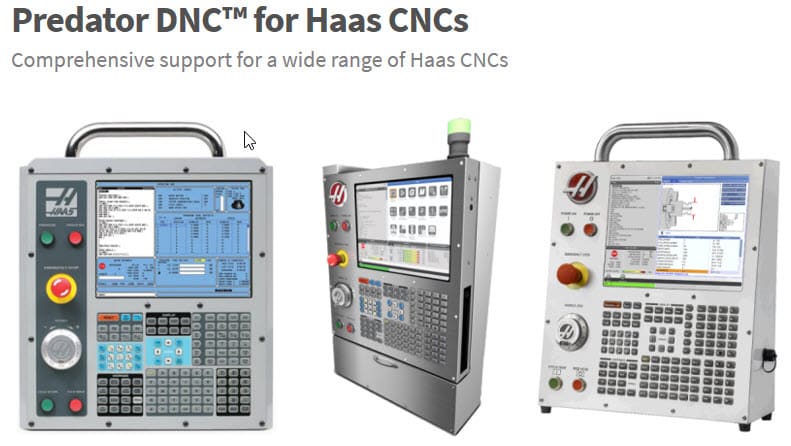

- Support for Xmodem on Fadal and Haas controls

- License 1, 2, 4, 8, 12, 16, or 8 port expansions as you grow

- Support Windows 10, 7 and Server 2019/2016

- Compatible with Virtual Operating Systems

- Upgrade to Predator Machine Monitoring or Product Data Management

- Free 30 day trial – no cost! Contact us via the sales form

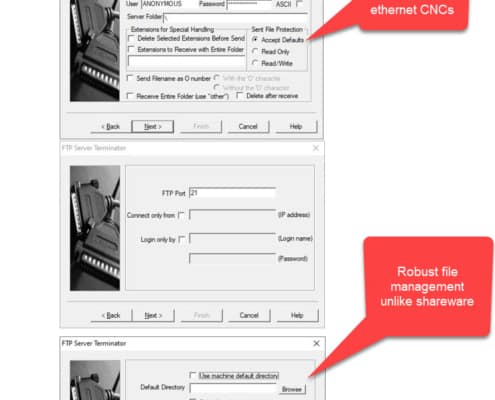

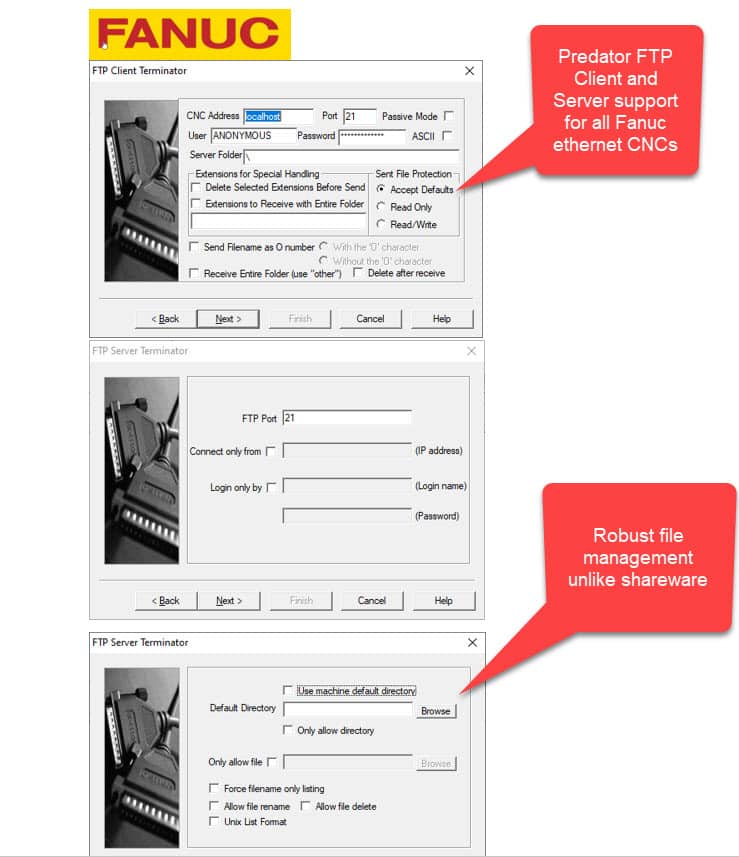

Ask us about Secure File Transfers using Secure DNC for Ethernet-based machines. Eliminate FileZilla, MoriServer, NetShare and more!

Overview

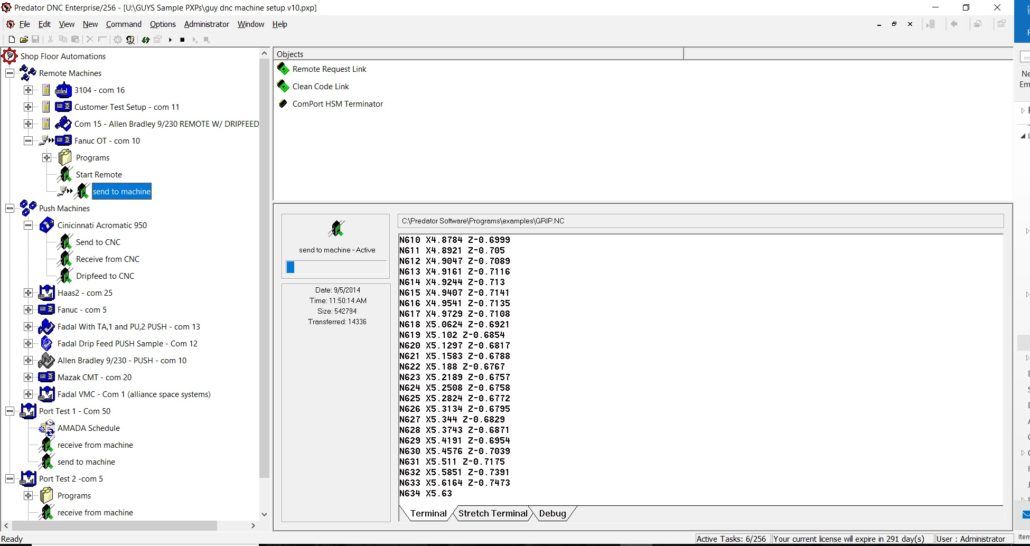

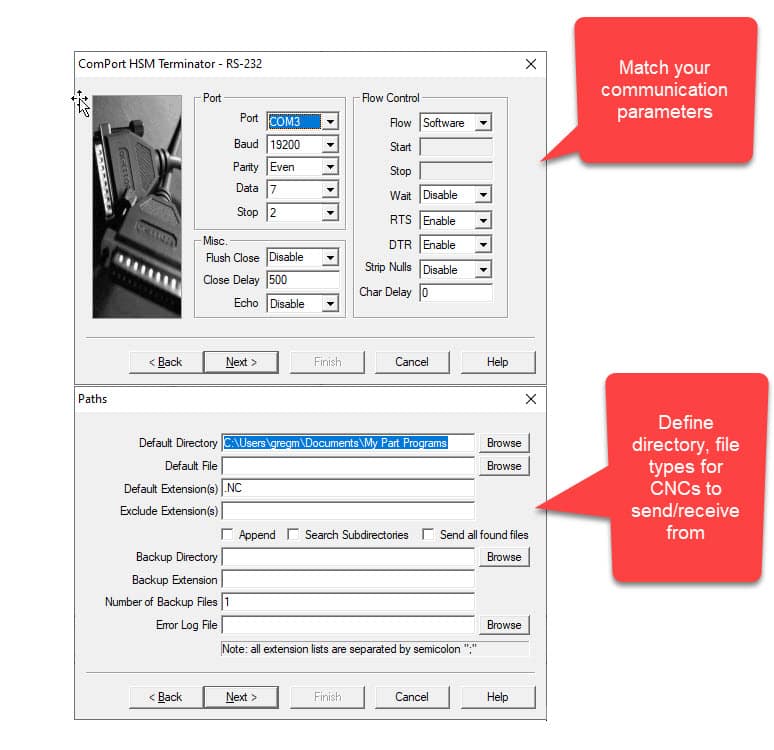

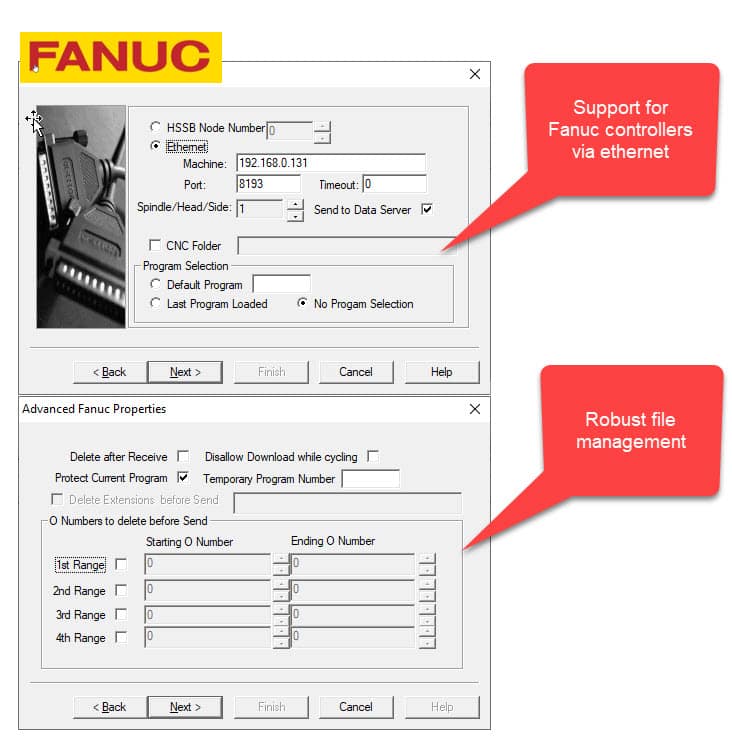

Predator DNC is software designed for DNC communication, allowing your organization to connect all your CNCs, Robots, and PLC-based machines on one industrial network. Predator DNC manages your CNC programs, offsets, and parameters, supporting a broad range of CNC communications for drip-feeding, downloading, and uploading via parallel, RS232, RS422 Ethernet, and wireless Ethernet. Control all of your files and work flow to transfer NC programs towards CMMC 2.0 compliance with a single application. The Predator DNC solution is developed and supported in the USA with worldwide installations since 1994.

Two Predator DNC Editions:

Predator DNC – Uploading/Downloading with advanced SecureDNC

Predator DNC Enterprise – Document Viewing/Email/Print + DNC

Improve the Workflow on the Shopfloor

One of the biggest benefits of Predator DNC is the improvement to your workflow on the shop floor. You will no longer need to carry laptops around or manually type part programs at the CNC. There’s no need to use legacy hardware to communicate, such as switch boxes and floppy disks. No hand signals or whistling to tell the operator to receive at the CNC.

Predator DNC Software

For more information from the #1 reseller of Predator Software, please call (877) 611-5825