We Can Implement All Types of Machine Monitoring

Machine monitoring has a wide variety of benefits. At Shop Floor Automations, we offer a variety of types of machine monitoring in Los Angeles CA, including:

- Scytec DataXchange on-premise or cloud-based machine monitoring to track multiple types of cycle time

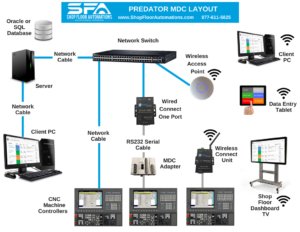

- Predator MDC (Machine Data Collection) to monitor 1 to 4,000 CNC machines

- MTConnect Protocol to collect data from various adapters

- Predator PDM to take your operations paperless

- Floppy Connect and replacement of other old shop floor media to replace your antiquated floppy disks and more

What Machine Monitoring Software Does Shop Floor Automations Offer?

At Shop Floor Automations, we only offer the top names in the industry. If you are wondering what options for machine monitoring in Los Angeles CA that we offer, keep reading to learn more:

Scytec DataXchange

- Cloud or on-premise. Real-time machine monitoring for improved OEE

- Real-time data from any CNC control/equipment, regardless of machine age

- Unlimited number of reporting and charting licenses

- View & report on your data results from anywhere

- Track multiple types of cycle time

- Use hardware adapters with protocols such as MTConnect or FANUC FOCAS

- Report on utilization and efficiency metrics

- Run reports on and compare different sets of cycle time

Predator MDC

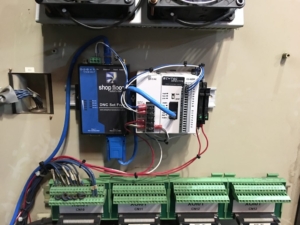

- Automatic and manual data collection

- 1 Network to monitor all your CNC machines, robots, PLCs and ATE test stands

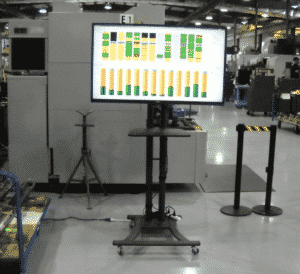

- 15 Real-time Dashboards for digital signage

- Real-time Slideshows for digital signage

- Multiple plant support

- Unlimited number of data collection events

- 30,000+ Reports and Charts

- Real-Time OEE Dashboard, OEE Charts, and OEE Reports

- Supports Wireless, Ethernet, RS232, and Parallel I/O

- Open API and database architecture

- Includes Predator CNC Service, Predator MDC Executive & Predator MDC for DOS

- Includes Predator DNC for send, receive, and drip-feed

- Use your existing ERP and MES bar coded paperwork

- Upgrade to Predator SFC

- 250+ Online help topics

- Integrates with Predator Touch HMI

We Offer Reliable Solutions for Machine Monitoring in Los Angeles CA

When it comes to having machine monitoring installed in your facility, Shop Floor Automations is the only company you should call. Since , we have installed machine monitoring in Los Angeles CA facilities and we would be happy to assist you as well. Give us a call today at (619) 461-4000 to request service or obtain a quote!

To learn more about the machine manufacturing software and machine automation services that we offer, visit us on the web at Shop Floor Automations.

In today’s competitive environment, you need to do everything possible to increase your bottom line. Thankfully, with machine monitoring in Houston TX, you can vastly improve your shop floor efficiency. Machine monitoring allows you to boost your lean manufacturing process, view real-time production data, make informed decisions, and drive improvements. If you are looking to implement machine monitoring in Houston TX, Shop Floor Automations can help.

In today’s competitive environment, you need to do everything possible to increase your bottom line. Thankfully, with machine monitoring in Houston TX, you can vastly improve your shop floor efficiency. Machine monitoring allows you to boost your lean manufacturing process, view real-time production data, make informed decisions, and drive improvements. If you are looking to implement machine monitoring in Houston TX, Shop Floor Automations can help.

In today’s competitive markets, it is essential to do everything in your power to improve your bottom line. That includes boosting your shop floor efficiency. Thankfully, with machine monitoring software, you can do just that.

In today’s competitive markets, it is essential to do everything in your power to improve your bottom line. That includes boosting your shop floor efficiency. Thankfully, with machine monitoring software, you can do just that.

In today’s competitive environment, it is important that your shop floor is as efficient as possible. You want to lower costs and improve productivity and manufacturing software can help you do that. If you are interested in manufacturing software in Pasadena CA, Shop Floor Automations can help. In fact, we carry full lines of manufacturing software and hardware solutions that can help improve your shop floor efficiency.

In today’s competitive environment, it is important that your shop floor is as efficient as possible. You want to lower costs and improve productivity and manufacturing software can help you do that. If you are interested in manufacturing software in Pasadena CA, Shop Floor Automations can help. In fact, we carry full lines of manufacturing software and hardware solutions that can help improve your shop floor efficiency. Are you looking for a way to replace the floppy drives in your CNC machines? At Shop Floor Automations, we understand your frustration with floppy drives. Not only are they outdated, but they are expensive to replace and a hassle to deal with due to their unreliability. Thankfully, at Shop Floor Automations, we offer floppy drive emulators that can replace floppy disks on your shop floor. You might be wondering if our floppy drive emulator is compatible with Haas machines, and the good news is, we have a specific Haas Floppy Drive Emulator that is only for Haas machines.

Are you looking for a way to replace the floppy drives in your CNC machines? At Shop Floor Automations, we understand your frustration with floppy drives. Not only are they outdated, but they are expensive to replace and a hassle to deal with due to their unreliability. Thankfully, at Shop Floor Automations, we offer floppy drive emulators that can replace floppy disks on your shop floor. You might be wondering if our floppy drive emulator is compatible with Haas machines, and the good news is, we have a specific Haas Floppy Drive Emulator that is only for Haas machines.