What is DNC Software?

DNC Software enables you to manage CNC programs, machine parameters, and offsets on a single network. This type of software allows a wide range of CNC communication options from your PCs to your DNC machines, and by implementing DNC Software in your Fort Worth TX facility, you can greatly improve shop floor efficiency.

Benefits of Installing DNC Software

There are numerous benefits that come with installing DNC Software at your facility. Some of these benefits include:

- Drip-feeding, downloading, and bi-directional communication

- Eliminates walking to and from CNC controls and PCs

- Improves CNC revision control

- Eliminates time wasted due to CNC communication failures

- Ability to manage machine files, remote requests, and file transfers

- Works on any machine because it is not just serial-based

- Enables you to drip-feed large programs

Types of DNC Software

There are two main types of DNC Software offered by Shop Floor Automations.

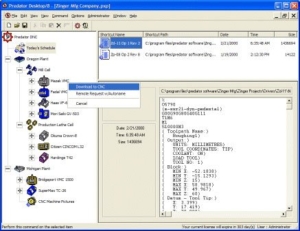

The first is Predator DNC Software. This package allows you to network all CNCs, EDMs, robots, and PLCs on one network. Major CNC protocols like Mazatrol (CMT), Okuma B, and Xmodem are all supported and you can send and receive drip-feed to up to 4,096 devices. With highly flexible interface options, you can easily communicate with your shop equipment via wireless, wired, USB, and Ethernet.

Ascendant eXtremeDNC Software is another type of quality DNC Software. This software allows you to push and pull files to CNCs from PCs remotely. You also gain reliable RS232 communication and support for Windows XP, Vista, 7, Server 2003/2008R2 – 32bit & 64bit systems. If you are looking to implement quality DNC Software in Fort Worth TX, Ascendant eXtremeDNC Software is a good option.

Contact Shop Floor Automations today for help implementing DNC Software in Fort Worth TX!

Are you ready to implement DNC Software at your facility in Fort Worth TX? If so, contact Shop Floor Automations today at (619) 461-4000 to learn more about the services we offer or request a quote. Whether you are looking to implement Ascendant eXtremeDNC Software to enable reliable RS232 communication via wireless and wired or Predator DNC Software, which networks all CNCs, EDMs, PLCs, and robots with singular DNC software, Shop Floor Automations can help. We’ve helped automate thousands of shop floor machines and would be happy to help improve the efficiency of your shop as well!

To learn more about the services, software, and hardware offered by Shop Floor Automations, please visit us on the web at Shop Floor Automations.

Manufacturing Day is held every year on the first Friday of October. The purpose of this national celebration is to encourage and inspire the next generation of manufacturers. Events are held across the country as manufacturers open their doors to students, parents, teachers, educational institutions, and community leaders, allowing them to get a first-hand look at what a manufacturing career entails.

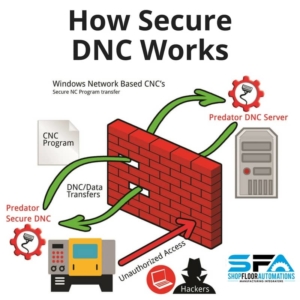

Manufacturing Day is held every year on the first Friday of October. The purpose of this national celebration is to encourage and inspire the next generation of manufacturers. Events are held across the country as manufacturers open their doors to students, parents, teachers, educational institutions, and community leaders, allowing them to get a first-hand look at what a manufacturing career entails. Corporate internet security systems can be complex, which often makes it difficult for shop floor machines to communicate effectively. If you are looking to securely transfer files to and from your shop floor equipment through company firewalls, Predator Secure DNC is the best option.

Corporate internet security systems can be complex, which often makes it difficult for shop floor machines to communicate effectively. If you are looking to securely transfer files to and from your shop floor equipment through company firewalls, Predator Secure DNC is the best option. Keeping your shop running efficiently and minimizing downtime is essential in today’s competitive landscape. Thankfully, DNC software allows you to link all of your CNC programs, offsets, and machine parameters on a single network. There are several options out there for DNC software, but Predator DNC far exceeds what free software alternatives are able to provide.

Keeping your shop running efficiently and minimizing downtime is essential in today’s competitive landscape. Thankfully, DNC software allows you to link all of your CNC programs, offsets, and machine parameters on a single network. There are several options out there for DNC software, but Predator DNC far exceeds what free software alternatives are able to provide. Since , Shop Floor Automations has helped countless clients automate their shop equipment and improve their overall efficiencies. With vast expertise and hardware solutions for over 80 brands and hundreds of controllers, you can trust Shop Floor Automations with your machine automation and monitoring. Based in La Mesa, California, we have the hardware, software, and expertise necessary to help take your shop floor equipment to the next level.

Since , Shop Floor Automations has helped countless clients automate their shop equipment and improve their overall efficiencies. With vast expertise and hardware solutions for over 80 brands and hundreds of controllers, you can trust Shop Floor Automations with your machine automation and monitoring. Based in La Mesa, California, we have the hardware, software, and expertise necessary to help take your shop floor equipment to the next level. MTConnect is a royalty-free, open factory floor communication standard that is specifically designed for the shop floor environment. This protocol enables data to transfer efficiently between devices and applications across the shop floor. Running machines, controls, software, and sensor packages with the MTConnect standard means that this data is available in XML format in a universal standard that won’t vary by manufacturer.

MTConnect is a royalty-free, open factory floor communication standard that is specifically designed for the shop floor environment. This protocol enables data to transfer efficiently between devices and applications across the shop floor. Running machines, controls, software, and sensor packages with the MTConnect standard means that this data is available in XML format in a universal standard that won’t vary by manufacturer. Manufacturing is always evolving. As a result, machinists that used to have a leg up on the competition are struggling to keep up with the diminishing skills gap that the industry is experiencing. As more CNC tools are becoming automated and demand for quality parts continues to grow, shops are putting an increased emphasis on improving productivity and efficiency. Time is money when it comes to CNC manufacturing and it is important to keep your operation running flawlessly. Keep reading for three tips for improving the efficiency and productivity of your manufacturing process.

Manufacturing is always evolving. As a result, machinists that used to have a leg up on the competition are struggling to keep up with the diminishing skills gap that the industry is experiencing. As more CNC tools are becoming automated and demand for quality parts continues to grow, shops are putting an increased emphasis on improving productivity and efficiency. Time is money when it comes to CNC manufacturing and it is important to keep your operation running flawlessly. Keep reading for three tips for improving the efficiency and productivity of your manufacturing process.