Are you considering implementing Scytec DataXchange in your shop? With Scytec DataXchange you can view OEE in real-time and modernize your shop floor. There are numerous benefits of installing Scytec DataXchange on your shop floor equipment so keep reading to learn more.

- Make Informed Decisions

With Scytec DataXchange, you can make informed, proactive decisions. The dashboard shows real-time shop floor data, automatically updates, rotates through screens, and allows you to view data from external systems. From utilization and feed rate to time spent in M0 and M1, downtime reasons, and part counts, Scytec DataXchange allows you to view the information you care about, whenever you want. That means you can make proactive decisions based on real-time information, instead of simply being reactionary.

- Get Real-Time Alerts

Another benefit that comes with Scytec DataXchange is access to email and text notifications. Instead of being tied to the dashboard searching for any issues, you can receive real-time alerts for a variety of parameters that you set. For example, if a machine is sitting idle for too long or running in low feed rate override for too long, you can receive a notification via email or text to alert you of the issues. That allows you to address an issue before it becomes larger problems.

- Unlimited Reports, Charts, and Users

With Scytec DataXchange, you also get access to unlimited reports, charts, and users for one rate. It’s not based on a per set/per license basis, which means all the decision makers and shop floor personnel can use it to their advantage. The dashboard can also be configured in a variety of ways to present the data in a way that makes sense for your operation. There’s an unlimited number of screens that can be configured to rotate, or filtered to view only certain equipment or statuses. With Scytec DataXchange, the power and flexibility are in your hands.

Contact Shop Floor Automations for help implementing Scytec DataXchange on your shop floor!

At Shop Floor Automations, we specialized in improving shop floor efficiencies. By installing Scytec DataXchange in your facility, we can help you modernize your shop floor and improve overall efficiency. We know the value in machine monitoring, which is why we offer affordable options that are easy on the budget. Not only do we provide flexible plans that include only the features you need but we also offer month to month options for our cloud product. From integrating Scytec DataXchange with ERP systems to assisting with Operator Interface troubleshooting, we do it all. Contact us today at (619) 461-4000 to request assistance or a quote.

To learn more about Scytec DataXchange and the machine monitoring hardware and software that we offer to make your shop floor more efficient, visit us on the web at shop floor.

Are you contemplating whether you should implement machine monitoring on your shop floor? With machine monitoring from Scytec DataXchange and the help of Shop Floor Automations, you can really take your operations to the next level.

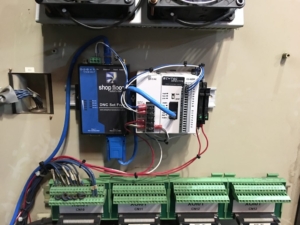

Are you contemplating whether you should implement machine monitoring on your shop floor? With machine monitoring from Scytec DataXchange and the help of Shop Floor Automations, you can really take your operations to the next level. If you are utilizing Scytec DataXchange, you may need to implement hardware with your shop floor equipment. That is where the Status Relay Controller comes into play. This device comes in two versions, SRC Standard and SRC Extended. Shop Floor Automations can help you determine which is right for your shop floor equipment.

If you are utilizing Scytec DataXchange, you may need to implement hardware with your shop floor equipment. That is where the Status Relay Controller comes into play. This device comes in two versions, SRC Standard and SRC Extended. Shop Floor Automations can help you determine which is right for your shop floor equipment.