If you aren’t sure if Predator Secure DNC is right for your facility, keep reading to learn more!

What is Predator Secure DNC?

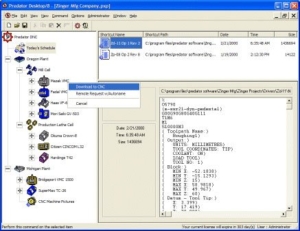

Predator Secure DNC is a Windows-based Predator application that helps make secure program transfers easier and safer across Windows-based CNC controllers. By allowing your CNC machine tool to interface with your network more easily, you can eliminate the requirements of corporate domains, workgroups, and Windows Shares for DNC transfers. This software allows you to securely transfer files to and from CNC machines through firewalls, which is important for shops that have strict network security.

Benefits of Utilizing Predator Secure DNC

There are many reasons that shops install Secure DNC, but one of the biggest reasons is the fact that there are so many benefits that come with the software. If you have an older CNC that is running a legacy operating system, Secure DNC eliminates the need for costly controller upgrades. With Predator Secure DNC, you can integrate all of your legacy equipment and create a common application between all equipment. It also creates transparent CNC network security and standardizes communication protocols to make it easier for your IT Department.

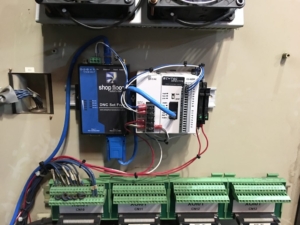

Shop Floor Automations Can Reduce IT Department Struggles

Connecting machines to a corporate network always comes with challenges. Not only does your IT department have to worry about increased security risks with connecting machines to the corporate network, but they also face other challenges including unsupported O/S, workgroups, homegroups, domains, NETBUI, FTP, IPS/SPX, and Windows Shares. Plus, there is time and money associated with maintaining the equipment. Thankfully, when you contract with Shop Floor Automations to implement Secure DNC, we can bridge the gap between your IT Department and the shop floor.

Contact Shop Floor Automations today to learn more about using Predator Secure DNC at your facility!

If you are interested in implementing Secure DNC, Shop Floor Automations can help. For over years, we’ve been helping clients with their machine monitoring and shop floor automation projects. Whether you are looking to implement Predator Secure DNC on some machines or need help automating your entire shop floor, trust the experts at Shop Floor Automations. Since , we’ve been working to help clients improve shop floor efficiencies and we’d be happy to offer our quality and affordable services to you as well. Call us today at (619) 461-4000 or email us at info@shopfloorautomations.com to request service.

To learn more about the shop floor automation services we offer at Shop Floor Automations, visit us on the web at Shop Floor Automations.

USB Connect solutions can eliminate the old technology on your CNC machines. They can also increase storage at the machine and allow you to store large part programs and use drip-feeding and other controls. By eliminating older technology like floppy disks, you can increase the efficiency of your shop floor and improve overall productivity.

USB Connect solutions can eliminate the old technology on your CNC machines. They can also increase storage at the machine and allow you to store large part programs and use drip-feeding and other controls. By eliminating older technology like floppy disks, you can increase the efficiency of your shop floor and improve overall productivity. Improving shop floor efficiencies is essential in today’s competitive market. Thankfully, you can take advantage of machine monitoring in Dallas TX to take your productivity to the next level. By utilizing machine monitoring, you can view in real-time what your shop floor equipment is doing and make informed decisions.

Improving shop floor efficiencies is essential in today’s competitive market. Thankfully, you can take advantage of machine monitoring in Dallas TX to take your productivity to the next level. By utilizing machine monitoring, you can view in real-time what your shop floor equipment is doing and make informed decisions. Predator DNC v11.0 was just released, updating its v10 predecessor. The latest version of Predator DNC comes with a bevy of updates that are intended to improve the software’s functionality.

Predator DNC v11.0 was just released, updating its v10 predecessor. The latest version of Predator DNC comes with a bevy of updates that are intended to improve the software’s functionality.