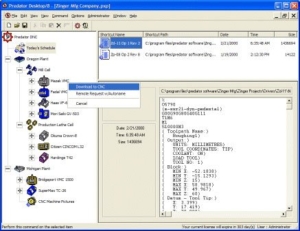

Predator DNC Software

At Shop Floor Automations, we use numerous Predator software packages to help our clients automate their shop floors and improve overall efficiencies. Predator DNC is a software that can greatly improve your shop floor efficiency. Known for being highly flexible, Predator CNC can work via wireless, wired, Ethernet, and USBs. It supports major CNC protocols like Mazatrol (CMT), Xmodem, and Okuma B, and allows for CNC DNC file transfers that are typically too large for CNC memory. Plus, you can easily upgrade to Predator PDM or MDC when you’re ready. This is one of the only programs that supports up to 4,096 machines, making it great for larger shop floors.

Ascendant eXtremeDNC Software

Ascendant eXtremeDNC Software is another DNC software that can improve your shop floor. This software first debuted in 1996 but has been updated to support newer operating systems. You can operate Ascendant eXtremeDNC Software on either wireless and wired systems, and with this DNC software, DNC communication for programs too large for CNC memory is achievable, as are successful CNC transfers. This open architecture system (OAS) has all of the necessary communication protocols and you can view essentially all graphical manufacturing files on demand. With applications like Adobe Acrobat and AutoView supported, Ascendant eXtremeDNC Software is a great DNC Software choice for many shop floors.

Benefits of Installing DNC Software in Dallas TX

When implementing DNC Software in Dallas TX, there are numerous benefits. Most importantly, the software eliminates walking time to and from CNC controls and PCs. Imagine not only the time you will save yourself but also how that saved time can benefit your overall operation. That in itself makes installing DNC Software enticing, but there are additional benefits, including:

- The ability to manage machine files, do remote requests, and transfer files

- Drip-feeding large programs and group them by building or cell

- Obtain RS232 CNC software for your shop floor

- Improve CNC revision control with ERP & MES bar-coded paperwork

Shop Floor Automations can implement DNC Software in Dallas TX.

With over years of experience, you can trust Shop Floor Automations to install DNC Software at your Dallas TX facility. Not only can we implement DNC software in Dallas TX, but we also have a vast array of software, hardware, and services that can help improve your shop floor efficiencies. Since , we’ve helped countless shops out by installing DNC Software. Contact us today at (619) 461-4000 to request DNC Software for your Dallas TX facility.

To learn more about the services, software, and hardware offered by Shop Floor Automations, please visit us on the web at Shop Floor Automations.

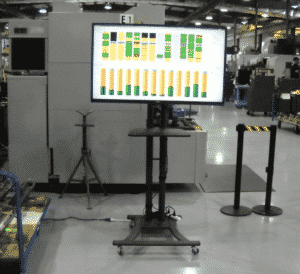

Facility managers have one main goal in mind and that is to keep the facility running smoothly. However, there are always other goals in the back of their mind, such as improving shop floor efficiencies. In order to do that, they need to be able to view real-time OEE information to truly identify areas for improvement. Thankfully, by installing machine monitoring like Predator software in Fort Worth TX, you can easily view real-time data, including cycle time, idle time, setup time, teardown time, machine downtime, and scrap reasons.

Facility managers have one main goal in mind and that is to keep the facility running smoothly. However, there are always other goals in the back of their mind, such as improving shop floor efficiencies. In order to do that, they need to be able to view real-time OEE information to truly identify areas for improvement. Thankfully, by installing machine monitoring like Predator software in Fort Worth TX, you can easily view real-time data, including cycle time, idle time, setup time, teardown time, machine downtime, and scrap reasons. In a competitive environment, maintaining an advantage over the competition is essential. Are you tired of wasting time walking to and from your CNC control and computer? Are you wondering if there is a better way to network and communicate with your machines? Improving shop efficiencies is important to keep productivity—and profits—high, and by implementing DNC Software in your Fort Worth TX facility, you can do just that.

In a competitive environment, maintaining an advantage over the competition is essential. Are you tired of wasting time walking to and from your CNC control and computer? Are you wondering if there is a better way to network and communicate with your machines? Improving shop efficiencies is important to keep productivity—and profits—high, and by implementing DNC Software in your Fort Worth TX facility, you can do just that. Manufacturing Day is held every year on the first Friday of October. The purpose of this national celebration is to encourage and inspire the next generation of manufacturers. Events are held across the country as manufacturers open their doors to students, parents, teachers, educational institutions, and community leaders, allowing them to get a first-hand look at what a manufacturing career entails.

Manufacturing Day is held every year on the first Friday of October. The purpose of this national celebration is to encourage and inspire the next generation of manufacturers. Events are held across the country as manufacturers open their doors to students, parents, teachers, educational institutions, and community leaders, allowing them to get a first-hand look at what a manufacturing career entails.