Moldmaking is a rewarding area in our industry to work within. Plastic manufacturing touches many facets of our daily lives. Just ask those who work in the field!

“Moldmaking and injection molding is at the very heart of the plastics industry,” says Nishit Shah, Mold Design Engineer at Nypromold.

Moldmaking Technology released an in-depth piece where they interviewed plastic manufacturers. Nypromold was the highlighted company in the article.

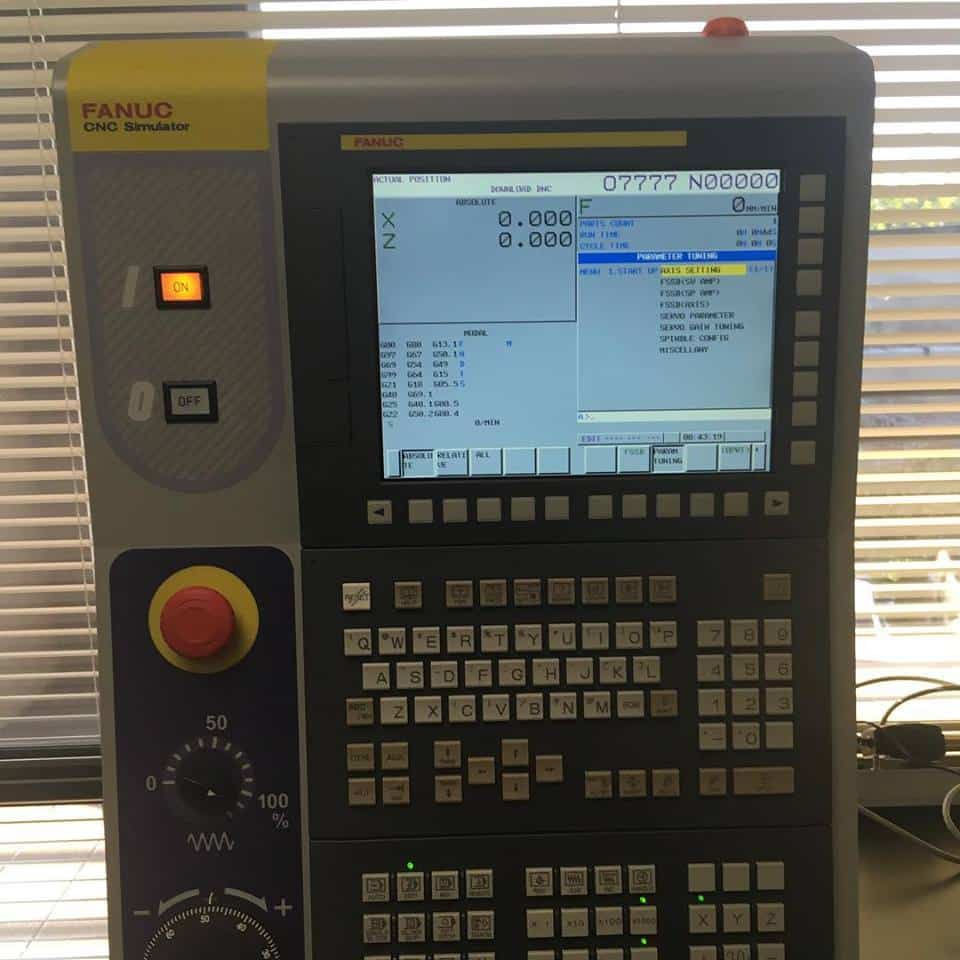

“What brought me to manufacturing was the ability to use advanced technology,” says Keene Huntoon, a CNC M

“We take plastic pellets, melt them in the machine, and inject them into the mold,” says Amber Zapatka, Plastics Engineer. Holding both a Bachelors and Masters in Plastics Engineering, she states her work is like a puzzle.

“What’s the best way and fastest way to make good parts each time?” Amber and other employees in her field are constantly looking for ways to improve their processes.

What are the best ways for plastic manufacturers to increase their productivity? Check out these resources below:

- Three Reasons Moldmakers need IIoT ARTICLE

- Reducing Moldmaking Downtime ARTICLE

- Why DNC Software is Crucial for Moldmakers ARTICLE

Ready to increase productivity? We service moldmakers, CNC machine shops, metal fabricators, and more manufacturers within our industry. Call (877) 611-5825 or have us contact you