Picking up a new software system can be challenging. DataXchange makes the process easy with lots of resources.

Picking up a new software system can be challenging. DataXchange makes the process easy with lots of resources.

DataXchange machine monitoring software is a solution for manufacturing companies. The benefits are decreases in downtime, increasing machine capacity, and real-time notifications of machine issues.

Machinists can enter notes if material is needed or lockout/tagout occurs. Shop floor managers can also be notified of unplanned downtime.

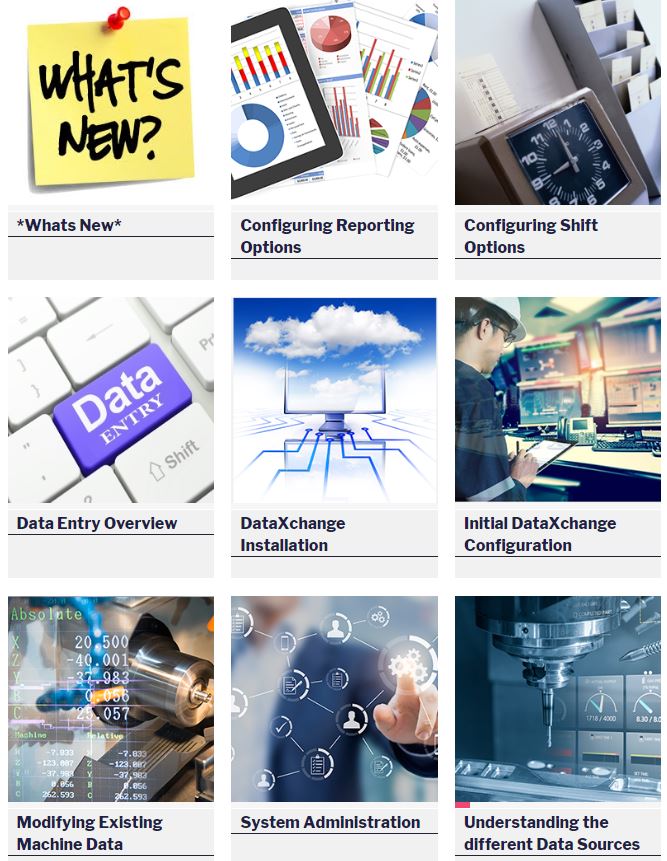

Here are the top resources on how to learn to use this machine monitoring software system:

1) Videos & FAQs – Use quick videos on how to use specific parts of the software system. Look at how to use the data entry screen or how to use the modified time stamp. If you have specific questions, it has also likely be answered in our FAQ section focused on DataXchange.

2) DataXchange E-Learning – 12 months of access to video courses on every aspect of DataXchange. This is the best option for beginners, or if you want to train someone else to use it.

The courses cover the topics of installation, equipment/reporting groups, schedule reports, shifts/shift assignments, modifying machine data, MTConnect, Fanuc FOCAS, specific troubleshooting, configuration, and more. Each section has a quiz and the courses can be revisited for a refresher.

Request info on DataXchange E-Learning

3) Schedule a Webinar/Demo – Be part of a DataXchange webinar, or request a software demo. This is the best way to ask specific product questions and get a taste if this software is correct for you.

We encourage you to get in touch with us by calling (877) 611-5825 or schedule a demo/webinar above.

Shop Floor Automations is the #1 reseller of DataXchange and we are always happy to have a conversation about the machine monitoring system!

Picking up a new software system can be challenging. DataXchange makes the process easy with lots of resources.

Picking up a new software system can be challenging. DataXchange makes the process easy with lots of resources. This archived issue of the Shop Floor Automations newsletter was

This archived issue of the Shop Floor Automations newsletter was

“Titan”: rooting from Greek mythology, it means a person or figure of great importance or power. Have you heard of the Titan who started a free CNC learning program called Titans of CNC?

“Titan”: rooting from Greek mythology, it means a person or figure of great importance or power. Have you heard of the Titan who started a free CNC learning program called Titans of CNC? Haas Automation is celebrating the 30th anniversary of their Haas VF-1 vertical machining center with Haas Demo Day 2018!

Haas Automation is celebrating the 30th anniversary of their Haas VF-1 vertical machining center with Haas Demo Day 2018! We get many calls to our office asking questions about CNC floppy emulator hardware. While we invite you to contact us for more detailed information, we want to answer the most asked question: Does your Floppy Connect hardware add memory to my machine?

We get many calls to our office asking questions about CNC floppy emulator hardware. While we invite you to contact us for more detailed information, we want to answer the most asked question: Does your Floppy Connect hardware add memory to my machine? How many programs you can store on the USB stick is another big question we get. Since the customer is going from a disk that was once 720k or 1.4MB to a 1GB SFA USB stick, the assumption is that they can store and send big programs from it. This is incorrect.

How many programs you can store on the USB stick is another big question we get. Since the customer is going from a disk that was once 720k or 1.4MB to a 1GB SFA USB stick, the assumption is that they can store and send big programs from it. This is incorrect. Last week, the long-awaited official trailer for documentary Masters of Resonance premiered. The film follows the path of how a quality drum set is made – from the raw material being sourced, to the concept of the product, to the making of it, to where it actually goes.

Last week, the long-awaited official trailer for documentary Masters of Resonance premiered. The film follows the path of how a quality drum set is made – from the raw material being sourced, to the concept of the product, to the making of it, to where it actually goes. Here is more archived SFA press coverage. Controlling CNC programming with DNC software is part of the focus.

Here is more archived SFA press coverage. Controlling CNC programming with DNC software is part of the focus.