Predator MDC Video

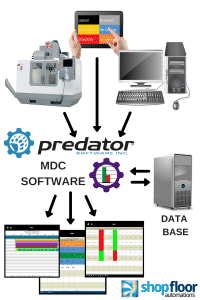

Predator MDC creates a continuously up to date knowledge base of your manufacturing performance. It quantifies how well your machines, people and parts are produced. Predator MDC can establish and compare continuous improvement results for lean manufacturing efforts. Predator MDC organizes your real-time data into actionable metrics for availability, quality and performance. Metrics for specific machines or rolled up metrics for an entire department across multiple plants are available with a few mouse clicks. Refer to the following major features

Predator MDC supports automatic, error-free, and unattended machine monitoring for events such as job start and end, setup start and end, cycle start and end, to name a few of the events that can be monitored. This type of data is collected automatically using software, hardware, custom macros and other methods without requiring operator training or input.

Predator MDC supports up to 4096 CNC machines, robots, PLCs, ATE Test Stands, band saws, dot peen markers and other equipment per PC for simultaneous cycle time, setup time, teardown time, downtimes with reasons, good parts, scrap parts with reasons and an unlimited number of user defined events.

Keep score of your shop floor productivity with Predator MDC. Every second is tracked per machine, job, part, operation, shift and person. Real-time dashboards displays current machine, part, job, operation and personnel status. Multiple engineers, supervisors and managers can view the dashboard from any networked PC. Leverage the power of the Internet and VPN from anywhere in the world to see the status of your shop floor.

Dedicate one or more large screen monitors on the shop floor for real-time digital signage. Create slides of charts, dashboards and reports with specific filters and details. Eliminate manual posting of paper reports and charts. Provide a focal point for standup shop meetings while enforcing productivity and manufacturing metrics that management, engineering and quality departments care about.

Want more information? Call (877) 611-5825 and ask us how we can help you increase OEE on your shop floor!

Floppy Drive Emulators and Serial Port Accessories

Floppy Drive Emulators and Serial Port Accessories