The following is an archived copy of the Shop Floor Automations Newsletter – May 2011.

The manufacturing industry continues to grow and the upswing

* Data Collection Made Simple*

*Scheduling is Quick and Easy *

Link to original newsletter HERE

The manufacturing industry continues to grow and the upswing

* Data Collection Made Simple*

*Scheduling is Quick and Easy *

Link to original newsletter HERE

Jobpack Production Scheduling

Jobpack Production SchedulingScheduling is the key to efficient operations. With Jobpack Production Scheduling software, you can quickly identify bottlenecks and react in real-time to unexpected production problems.

You’ll know what job to run next, when to promise the customer’s order, and what machines can get it done the fastest. You can optimize production capabilities while achieving realistic delivery dates to keep customer satisfaction humming right along.

Job Scheduling Software is essential for knowing if deliveries will be on time. It takes all of your current jobs, along with capacity, & gives you the ability to see where your jobs are & when they are going to be completed. The real-time scheduling module keeps operators on the shop floor up to date with what jobs to run next. Sudden downtime on machines is accounted for & re-scheduling based on new machine capacity can happen.

With a solid scheduling system in place, you’ll be better equipped to update your customers on delivery dates and identify late deliveries before they happen so you have time to do something about it. Displays of pre-order & estimated cost calculations, as well as actual costs incurred during manufacture, are shown as they occur, as well as displaying data for groups or individual cells of machines.

Learn More

Features include:

Real-time machine data collection

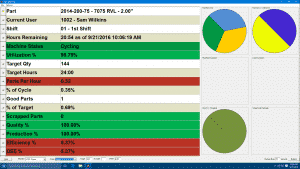

Real-time machine data collectionCapturing real-time data from the shop floor does not have to be complicated. Using your existing infrastructure and computers, our data collection solution Predator MDC can be added to your equipment with ease. Here is info on Data Collection for CNC Machines made simple.

Works with any type of CNC control, including Mazak, FANUC, Haas, Okuma, Siemens, and Cincinnati. Compatibility also includes Robots, press brakes, bar feeds, welders, and more.

Report, chart and display on any workstation or LCD Monitor the current status of the machine to start. Later, you can expand multiple plants, capture jobs, part counts, scrap reason and more with our Enterprise MDC. Learn More

More about our Machine Monitoring and Data Collection services through Predator MDC, as well as Scytec DataXchange:

Machine Monitoring gives you the ability to see what your machines are doing in real-time. Collect & process data from your machines using software like MTConnect, FANUC FOCAS, custom macros, or hardware devices. Optional data collection terminals can be used for additional operator input. Run time, downtime, & OEE data is then presented via dashboards, historical reports, & charts. Emails or text messages can be sent to notify you of production issues on the shop floor.

Improve manufacturing by supplying accurate shop floor productivity metrics to improve operations & make better decisions. Enjoy automatic, error-free, & unattended machine monitoring for events such as job start/end, setup start/end, log on/off, cycle start/end, & more. Data collected includes cycle time, idle time, setup time, teardown time, machine downtime, & scrap reasons.

Founded in 1998, we have delivered on our promise to thousands of customers with proven software from Scytec, Ascendant Technologies & Predator Software. We have automated thousands of manufacturing machines with hardware while partnering with numerous companies to increase shop floor efficiencies & profits.

2023 © Copyright – Shop Floor Automations

5360 Jackson Drive

Suite 202

La Mesa, CA 91942

(877) 611-5825 Toll Free

(619) 461-4000 Main

Our business hours:

7 AM to 4 PM Pacific Time

Monday to Friday