The Writing on the Wall

The indicators to diversify your customer base can present themselves in many ways to a company. Value Prop, a B2B strategy consultancy, defines “customer concentration” as when companies have more than 10% of revenue reliant on a single client – or if revenue portions greater than 10% rely on multiple single clients. For Senior Aerospace AMT, a leading manufacturer of commercial and aerospace parts, its single customer of the company – albeit, one of the largest aerospace companies in the world – made up approximately 90 percent of AMT’s business. The company spun this indicator into an opportunity to fine-tune its machining operations.

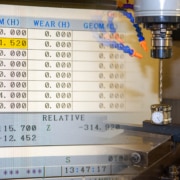

While piloting the DataXchange machine monitoring solution, the AMT team decided to leverage the existing PCs at each work center so there wasn’t a need to train operators on new hardware in addition to new software.

Tom Anderson, AMT Machine Process Engineer, explained, “We wanted to know, how much time are machines broken down? Which machines need to be replaced over others, and when? At the same time, we wanted to get a full sense of our capacity.” Once this visibility was gained, he figured, there would be a better chance to determine potential improvements to cost effectiveness and quality in an effort to retain current business and attract new prospects.

“It was really easy, out-of-the-box. You can collect infinite types of data.”

AMT partnered with Shop Floor Automations (SFA), a California-based provider of hardware, software and technical expertise, for options. The DataXchange aerospace machine monitoring solution, by Scytec Consulting, was recommended after an evaluation of AMT’s requirements. “We wanted to walk before we run,” he noted, sparking a pilot approach to the implementation of the software. Six machines, some with tablets or bar code scanners, were connected by the IT team at AMT during the first phase of the pilot.

The Team Takes Off

“It was really easy, out-of-the-box,” he says. The tools and documentation available through the platform were enough for Anderson and his team to start setting up the program in-house. “You can collect infinite types of data, so we looked to simplify above all else.” For example, machine statuses were set up to indicate the lack of an operator.

Initially the team input 15-20 downtime options to select from; those options were then narrowed to 8-9 with a reason code and the ability to add a note for further information. At the same time, the team decided to leverage the existing PCs at each work center so there wasn’t a need to train operators on new hardware in addition to the DataXchange software.

Learn more about the approach AMT took with its aerospace machine monitoring software by accessing the full success story now.

Application Requirements:

Application Requirements: