A long standing publication with a classic newspaper vibe – we are proud to have been featured in Manufacturing News many times. The issues focus on different regions and their varying Made in America goals.

Here are some recent pieces that Manufacturing News have featured us in:

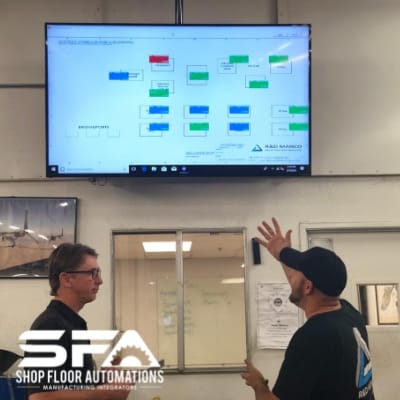

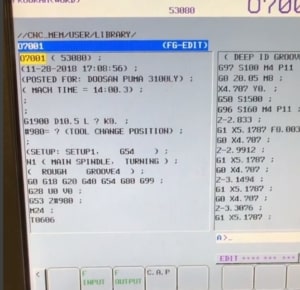

Our case study with R & D Manco in Arizona appears in the December 2018 issue. This manufacturer previously had experience with our CNC Editor software and our hardware. However, they implemented an on-premise machine monitoring system after a pilot program. Because of this, they boosted their productivity in a short period of time.

Proving return on investment for automation solutions can be complicated. Because of this, we created an article for decision makers on how to lay these details out. Some pieces of valuable information in this process are equipment compatibility, evaluating processes and having alternative options available. This article appears in the November 2018 issue.

The medical manufacturing industry is a very high-volume business. We constantly work with these shops to find the best automation solutions for them. Specifically, we always recommend OEE (overall equipment efficiency) monitoring. The top four benefits to this software appear in the April 2018 issue.

Check out our other articles on similar manufacturing solutions. Ready to start the conversation about shop floor automation? Call (877) 611-5825 or fill out an online contact form

Mr. Mercurio spent two hours touring the facility and talking to managers as well as trainees currently in the program. “The experience changed my perception,” Mr. Mercurio recalls.

Mr. Mercurio spent two hours touring the facility and talking to managers as well as trainees currently in the program. “The experience changed my perception,” Mr. Mercurio recalls.

Want RS232 to USB hardware results before purchasing? Check out this case study with Fredon Corporation!

Want RS232 to USB hardware results before purchasing? Check out this case study with Fredon Corporation! In the latest round of digital coverage for Shop Floor Automations (SFA), which includes a few MoldMaking Technology pieces:

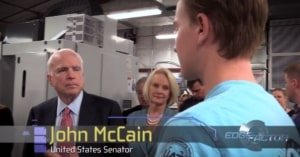

In the latest round of digital coverage for Shop Floor Automations (SFA), which includes a few MoldMaking Technology pieces: Aerospace. Medical. Defense. Skateboarding?! Shop Floor Automations loves fulfilling needs for unconventional manufacturers, so when we learned our customer Professor Schmitt (Paul Schmitt of PS Stix Inc) was going to be the focus of the Edge Factor documentary “Happy Accident”, we were very excited!

Aerospace. Medical. Defense. Skateboarding?! Shop Floor Automations loves fulfilling needs for unconventional manufacturers, so when we learned our customer Professor Schmitt (Paul Schmitt of PS Stix Inc) was going to be the focus of the Edge Factor documentary “Happy Accident”, we were very excited! Another documentary to check out from Edge Factor is “Full Circle.” The unexpectedly emotional film focuses on unintentional connections we make in the manufacturing industry and how it helps us all fill the manufacturing skills gap.

Another documentary to check out from Edge Factor is “Full Circle.” The unexpectedly emotional film focuses on unintentional connections we make in the manufacturing industry and how it helps us all fill the manufacturing skills gap. Sam Wilkins, Technical Operations Manager at Shop Floor Automations, has earned a spot in the SME 30 Under 30 List.

Sam Wilkins, Technical Operations Manager at Shop Floor Automations, has earned a spot in the SME 30 Under 30 List.