When optimal productivity and efficiency are attained on the shop floor, why carry on equipment monitoring efforts indefinitely?

When MOGAS, the leading manufacturer of severe service ball valves, began monitoring their equipment on the shop floor, they started realizing real value within the first two weeks.

“I was receiving frequent machine alerts with operator notes indicating ‘part move’ during tooling downtime for a part that was taking 8 hours to make,” says MOGAS Machine Shop Leadman Hector Reyes, who is a 9-year veteran of the company and handles router workflows to the machines. “After talking with the operator, I learned that the existing fixture was forcing numerous adjustments. By designing a new fixture to better hold the part, we were able to shave off about 5 hours of machine time.”

Monitoring Plateaus

Within a year of implementing the equipment monitoring solution, DataXchange, MOGAS saw a 62.5% decrease in machine time as a result of time-saving alerts and a 10% increase in efficiency. Tech Manufacturing, an ADDMAN company that specializes in medium-to-large, complex parts with tight tolerances, reported reaching an efficiency of 65 percent after bringing on its machine monitoring program. The goal was to achieve 70 percent, recounted Modern Machine Shop, but diminishing returns had started to set in and efficiency improvements were linked “to increasingly minor or increasingly rare events.”

Within a year of implementing its equipment monitoring solution, MOGAS saw a 62.5% decrease in machine time as a result of time-saving alerts and a 10% increase in efficiency.

For manufacturers looking ahead – or currently experiencing high optimization with their machine monitoring system – how do you continue to justify the expense of such a solution once this state of near perfection is reached?

The answer is simple, says Greg Mercurio, president of manufacturing integrator Shop Floor Automations (SFA). “The optimization of your equipment is not a one-time process,” he says. “The condition of machines change over time: they’re impacted by fluctuating and extreme temperatures; wear and tear; the breakdown of their components; poor preventive maintenance and other factors.” While it can be tempting to think you’ve taken things as far as you can, there’s always the potential for deviation on the horizon. Mercurio explains, “Add in the changing workforce, new hires and a labor pool with mixed technical abilities, and you’ll still face the potential for errors and other issues.” Without consistent machine monitoring in place, those issues can go unnoticed over great lengths of time and threaten optimized states, potentially significantly.

Early Detection for Best Prevention

To learn how you can maximize your machine monitoring program for the long-term, contact Shop Floor Automations today.

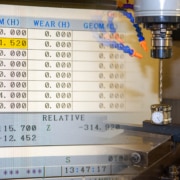

Machine Monitoring to them. Since many shops have a wide variety of machines to handle various needs, it is important to know what we can connect far more than just CNC’s.

Machine Monitoring to them. Since many shops have a wide variety of machines to handle various needs, it is important to know what we can connect far more than just CNC’s. Flexible CNC communication firmware is built into the unit. This allows for a connection to a large variety of machine tool controls. The device buffers the entire program at the machine, and acts as a dedicated computer that responds instantaneously to data flow changes from the CNC.

Flexible CNC communication firmware is built into the unit. This allows for a connection to a large variety of machine tool controls. The device buffers the entire program at the machine, and acts as a dedicated computer that responds instantaneously to data flow changes from the CNC.