Production Machining Magazine

Production Machining Magazine

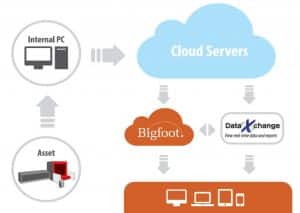

There is a good article about CMMS (computerized maintenance management system) from Bigfoot CMMS in the April 2014 edition of Production Machining. Shop Floor Automations provides an excellent solution for those needs.

Automation is what is propelling manufacturing today, and I’m not only talking about machine tool automation. Automation can and does occur in the office as well with the implementation of shop management software and tool data management software.

A computerized maintenance management system (CMMS) is one example of a tool that automates preventive maintenance schedules on shop equipment. This system can improve the bottom line through increased labor efficiency, enhanced asset effectiveness, certification assistance with government agencies and certifying organizations, liability protection and more.

A CMMS monitors pressure, temperature, voltage and hours run and help operators communicate when maintenance should be completed. It can also track equipment history and grade performance over time. The software can reduce equipment downtime, minimize equipment and cost repairs, maximize equipment reliability and increase efficiency.

Read “Investing in a Computerized Maintenance Management System” for more information about the CMMS.

Other options for shop management software include scheduling software such as the one in described in “Profiting with Shop Management Software” and modular tool data management software that allows users to take tool data anywhere that it is needed, from purchasing to design and engineering to CAD/CAM to the tool crib and assembly, all in one database. Read more in “Integrated Tool Management with CAD/CAM Connection.”

Get more info or check out the full article in Production Machining

Production Machining Magazine

Production Machining Magazine The following is an archived copy of the Shop Floor Automations Newsletter – May/June 2014 issue.

The following is an archived copy of the Shop Floor Automations Newsletter – May/June 2014 issue.